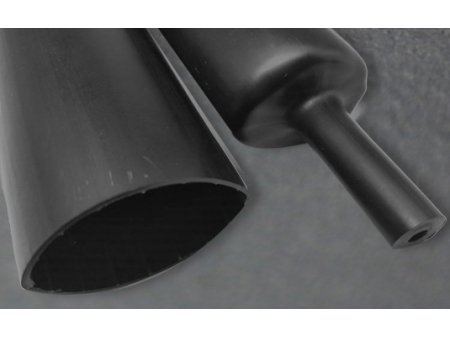

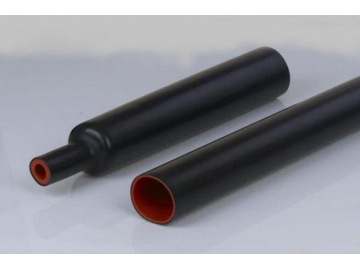

Medium-Wall Heat Shrink Tubing (Dual Wall)

Request a Quote

CYG-HWTA

Semi-Rigid Electronic Insulation Heat Shrink Tubing for Communications

- Outer jacket: Cross-linked modified polyolefin

- Inner wall: Modified hot melt adhesive

- Shrink ratio: 3.5:1, 4:1

- High shrinkage ratio, accommodating larger diameters

- Black outer layer with high UV resistance

Applications

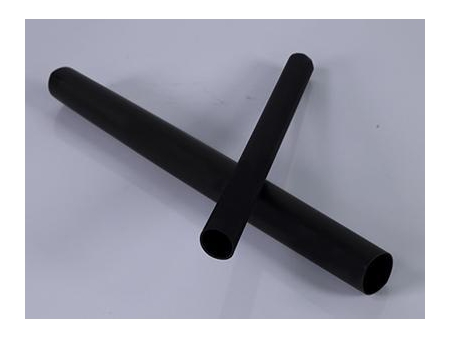

- The polyolefin material used in our tubing offers superior electronic insulation and mechanical protection. With its high shrinkage ratios, this heat shrink tubing is ideal for connecting a wide range of wire bundles or components.

- Its thick wall design is especially suitable for electronic insulation and mechanical protection of medium and high-voltage power cables. The inner layer's hot-melt adhesive provides waterproof sealing for connected components.

Features

- High shrinkage ratio, accommodating larger diameters

- Black outer layer with high UV resistance

- Semi-rigid polyolefin material for superior electronic insulation and mechanical protection

- Lowest full shrink temperature: 135°C

| Properties | Test Method | Performance |

| Continuous operating temperature (℃) | IEC 216 | -55~110 |

| Tensile strength (MPa) | ASTM D2671 | ≥14 |

| Ultimate elongation (%) | ASTM D2671 | ≥400 |

| Heat aging | 150℃, 168h | - |

| Tensile strength after aging (MPa) | ASTM D2671 | ≥12 |

| Ultimate elongation after aging (%) | ASTM D2671 | ≥300 |

| Volume resistivity (Ω·cm) | IEC 93 | ≥1.0*1014Ω·cm |

| Dielectric strength (kV/mm) | IEC 243 | ≥20 |

| Longitudinal change (%) | UL224 | 0~10 |

| Concentricity (%) | ASTM D2671 | ≥65 |

| Cracking resistance | ASTMD1693(50℃) | No cracking |

| Water absorption (%) | ISO 62 | 0.2 |

| Hot melt adhesive | ||

| Softening point (℃) | ASTMD E28 | 85 |

| Peel strength (PE) | DIN 30672 | ≥4 |

| Copper stability (%) | ASTMD2671 | No corrosion |

| Resistance to fungus and decay | ISO 846 | Pass |

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos