Concrete Batching Plant HZS90

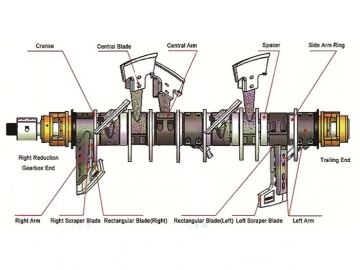

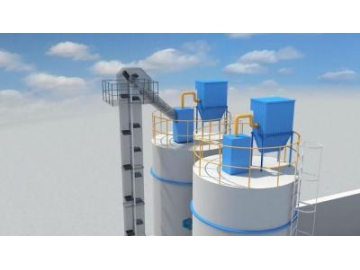

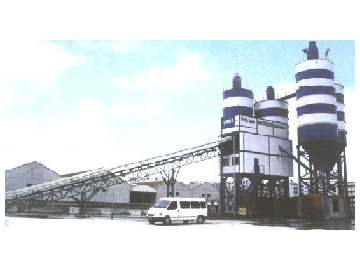

The HZS90 concrete batching plant is a large concrete machine integrating the storage, measuring, and mixing of materials with a production rate of 90m³/h. The cement mixer dispenses concrete at a height of 3.8m, and can mix various types of concrete, such as dry and hard concrete. Used in mid to large-sized construction and engineering projects involving water and electricity, roads, ports, docks, and bridges, the concrete mixing unit can store four different types of aggregates in its cement silos and corresponding spiral conveyor. Aggregates, additives, water and cement are all measured using precision electronic scales. The mixer uses twin-shafts for a thorough and efficient mixing quality. The concrete batching plant can be run either automatically or manually in case of power failure. If automatic, the dosing storage, drop automatic compensation, and alert systems are computer controlled. (Cement silo and spiral conveyor come separately). In addition, our concrete plant control system is bilingual.

Technical Parameters of the Concrete Batching Plant| Parameters | Model |

| Theoretical productivity | 960 m3 /h(117yd3/hr) |

| Mixer type | JS1500 |

| Mixer power | 2*30kw |

| Period of circulation | 60s |

| Nominal capacity of mixer | 1500L (352gal) |

| Max. aggregate grain | ¢ 80mm (3") |

| Capacity of filler bin | 2*100t |

| Batching capacity of batcher | 1600L (352gal) |

| Capacity of aggregate bin | 3*17 m3(3*22yd3) |

| Type of aggregate | 3 |

| Productivity of aggregate lifter | 210t/h |

| Max. productivity of screw conveyor | 110t/h |

| Discharge height | 3.8m (12'6'') |

| Power | 160kw |

| Scope and precision of the metage for cement | (0-1200)±1%kg |

| Scope and precision of the metage fo coal ash | (0-2645) ±1%lbs |

| Scope and precision of the metage for water | (0-400)±1%kg (0-882) ±1%lbs |

| Scope and precision of the metage for additive | (0-50)±1%kg (0-110) ±1%lbs |