Fully Automatic Blow Molding Machine

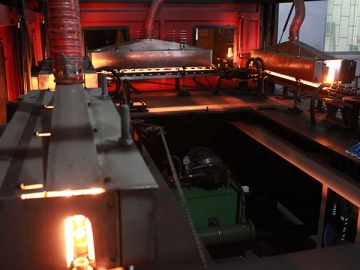

Fully- automatic blow molding machine

Controlled by human- computer interface, easy operation

The preform feeding system feeds the bottle preforms automatically the using a preform unscrambler.

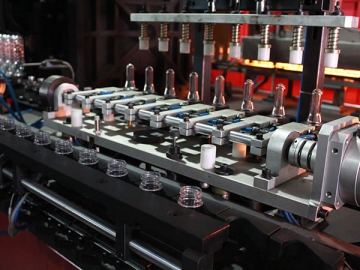

The fully automatic blow molding machine uses a single- channel servo preform feeding system, with uniform distribution, low failure points, and a stable performance.

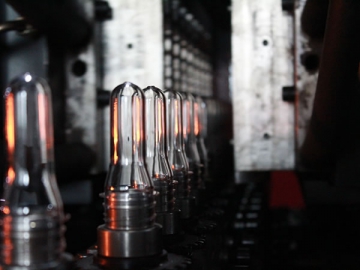

Stretching rod

Preforms and well- blown bottles

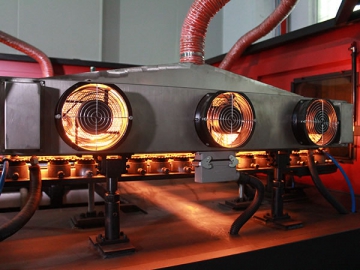

This blow molding machine uses a semi- enclosed incubator with variable frequency air- cooling or circulating water cooling double protection systems, in order to heat every bottle preform in an even manner, ensuring the bottle neck will not become deformed by the heat. A high production capacity is guaranteed, and the machine is 50% more energy- efficient than other similar products on the market today.

This machine uses a hydraulic mold closing system, with a double crank mechanical mold clamping system, bottom mold linkage system, four- plate molding system, and a double- side pressurizing system. It is steady and fast.

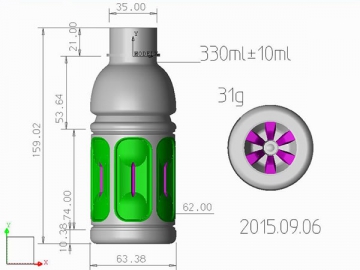

The ECP series is the most stable of our two- step, fully automatic PET stretch blow molding machines. It has 2 to 8 cavities, and the maximum capacity of the bottles is 2L. The blow molding machine can blow molds into different shapes, depending on the final application: carbonated drinks, mineral water, pesticides, cosmetics, wide- mouth, hot filling or other packing requirements. These bottles are made using crystalline plastic, such as PET or PP.

Main Control Part:

PLC: Siemens (Germany)

Pneumatic parts: FESTO (Germany )

Controller of preform transfer servo motor: Schneider (Japan)

Other electric parts are all world- famous brand: SMC, Parker, etc.

Performance:

- Stable performance with an advanced PLC control

- Conveying is performed automatically on the conveyor

- The machine features a strong penetrability, and excellent and fast distribution of the heat by allowing the bottles to rotate by themselves, and turn in the rails at the same time inside the infrared preheater.

- The blow molding machine is easily adjusted, ensuring the preheater heats the preforms into the right shape by adjusting the light tube and the length of the reflecting board in the preheating area, as well as the external temperature in the preheater with an automatic thermostat tool.

- This automatic blow molding machine is safe, with an automatic locking feature in the event of breakdown during the forming process.

- Different atmospheric pressures are available for blowing and mechanical actions, achieved by dividing the blowing and action into three parts in the air pressure diagram of the machine.

- The strong clamp force is high pressure and utilizes double crank links to lock the mold in place.

| Type | Item | |||||

| PET Container | Theoretical Output (Pcs/h) | 2300- 2700 | 3300- 3900 | 4500- 5000 | 6600- 7800 | 8800- 10000 |

| Max. Bottle Volume (L) | 2 | 2 | 2 | 0.7 | 0.7 | |

| Max. Bottle Neck (mm) | 38 | 38 | 38 | 38 | 38 | |

| Max. Bottle Height (mm) | 335 | 335 | 335 | 250 | 250 | |

| Max. Preform Height (mm) | 180 | 150 | 150 | 130 | 130 | |

| Mold Cavities (Pcs) | 2 | 3 | 4 | 6 | 8 | |

| Air System | Operation Low Pressure (Mpa) | 0.7 | 0.7 | 0.7 | 0.8- 1.0 | 0.8- 1.0 |

| Low Pressure Consuming (M3/Min) | 1.0- 1.5 | 1.0- 1.5 | 1.0- 1.5 | 2.0- 2.5 | 2.0- 2.5 | |

| Blowing High Pressure (Mpa) | 2.6- 3.5 | 2.6- 3.5 | 2.6- 3.5 | 2.6- 3.5 | 2.6- 3.5 | |

| High Pressure Consuming (M3/Min) | 1.5- 2.0 | 2.0- 2.5 | 4.0- 5.0 | 4.5- 6.0 | 6.0- 8.0 | |

| Water Chiller | Working Pressure (Mpa) | 0.3- 0.5 | 0.3- 0.5 | 0.3- 0.5 | 0.3- 0.5 | 0.3- 0.5 |

| Flow Rate (L/Min) | 40 | 40 | 40 | 50 | 70 | |

| Heating Part | Heating Unit (Pcs) | 3 | 3 | 3 | 4 | 4 |

| Heating Lamp Layer (Pcs) | 8 | 8 | 8 | 8 | 8 | |

| Heating Preforms Holder (Pcs) | 46 | 51 | 51 | 114 | 136 | |

| Electrical System | Total installed Power (KW) | 35 | 41 | 45 | 56 | 56 |

| Real Using Power (KW) | 12-18 | 15- 20 | 18- 22 | 22-30 | 25- 35 | |

| Frequency (V / HZ ) | 380 / 50 | 380 / 50 | 380 / 50 | 380 / 50 | 380 / 50 | |

| Machine | Main Machine Size (m) | 2.2*1.66*1.92 | 2.38*1.68*1.96 | 2.68*1.68*1.96 | 4.0*2.1*2.0 | 5.2*2.4*2.0 |

| Weight (Ton) | 4.0 | 4.2 | 4.8 | 7 | 9.5 |