9-10 Industrial Centrifugal Blower

The 9-10 industrial centrifugal blower is designed to handle high pressure air at ambient temperatures or under high temperature environments. Here are a few of many uses for this high pressure industrial centrifugal blower.

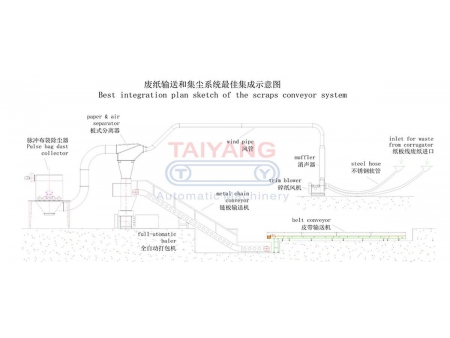

1. Supplying clean gas, combustible gas, corrosive gas, light dust loading gas, lightweight particles, scraps, or short fibers

2. Most popularly used as forced draft fans, and for fast drying, cooling and heat dissipation applications

3. Grate cooler on cement production line, cement clinker cooler, circulating fluidized bed system

4. Air purification, waste heat recovery, flue gas desulphurization

5. Used as forced draft fans or induced draft fans for industrial boilers or incinerators

9. Ventilating a large-scale grinding mill

10. Draft inducers for smelting furnaces and casting furnaces

11. Boosting combustion efficiency or pulverized coal ejection in a blast furnace

12. Increasing the pressure of coal gas to facilitate transportation

13. Furnace blowers

Model 9-08 as well as 9-10 provides the most industrial uses among other fan models.

Features of Industrial Centrifugal Blower

1. Whether your application involves high operating temperatures or high pressure environments, SIMO BLOWER has the appropriate industrial centrifugal blower for you.

2. Our industrial centrifugal blower is easy to install with the aid of a unitary base.

3. The bearing housing provides space to mount temperature sensor and vibration sensor. This is a great convenience as it allows users to monitor the fan operating status.

4. The motor load will automatically decrease as the resistance to air-stream increases. This automation feature prevents motor from burning.

5. Whether you are considering a standard centrifugal fan or one that is custom built to your specifications, please be confident that it will work for your application as each model is optimized by CFD technology to minimize energy consumption.

6. Tight-fitting parts provide a good seal, ensuring zero pressure loss.

7. Dynamically balanced impeller delivers high running stability.

8. Run test and vibration check are performed on the fan before it leaves factory.

9. When you specify or purchase our industrial centrifugal blower, be sure to consider our spare parts, too.

Specifications

| Application | Temperature | Ambient temperatures | |

| Hot Air | |||

| Media | Clean air | ||

| Corrosive gas | |||

| Combustible gas | |||

| Lightweight particles | |||

| Performance | Impeller diameter | 250-2000 | mm |

| Speed of main shaft | ≤4000 | rpm | |

| Pressure range | 348-15425 | Pa | |

| Flow range | 273-81858 | m3/h | |

| Structure | Blade | Forward-curved design | |

| Impeller Support | SWSI (Single Width, Single Inlet), overhung impeller. | ||

| Drive type | Direct drive (with flexible coupling) | Or determined by customers. | |

| Lubrication | Oil bath lubrication | Or determined by customers. | |

| Bearing cooling | Air cooling or Circulating Water cooling | ||

| System configuration | Motor | SIEMENS, ABB, SIMO, LA | Or determined by customers. |

| Impeller | Carbon steel | ||

| Impeller cone (Air Inlet) | Carbon steel | ||

| Impeller housing | Carbon steel | ||

| Air damper | Carbon steel | ||

| Main shaft | High-strength carbon structural steel | ||

| Bearing | FAG, SKF, ZWZ, C&U | ||

| Bearing housing | Cast iron | ||

| Drive type | Direct drive (with flexible coupling) | Or determined by customers. | |

| Foundation bolt | |||

| Options | System foundations, protective mesh screen, outlet pipeline expansion joint, outlet flange, motor rain cover, temperature sensor, vibration sensor, soft starter, inverter, specialized electrical motor, system monitoring instrument, lube system, overhead lube tank | ||

Direct Driven Centrifugal Blower (Forward Curved Blades, Double Inlet), SYZ Series

industrialair-blower.com

Direct Driven Centrifugal Blower (Forward Curved Blades, Double Inlet), SYZ Series

industrialair-blower.com

Belt Driven Centrifugal Blower (Backward Curved Blades, Dual Inlet), SYH Series

industrialair-blower.com

Belt Driven Centrifugal Blower (Backward Curved Blades, Dual Inlet), SYH Series

industrialair-blower.com