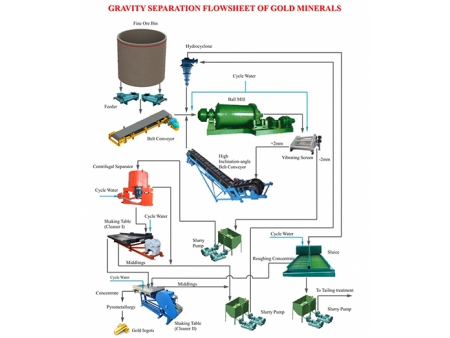

Mini Modular Gold Gravity Concentration Plant

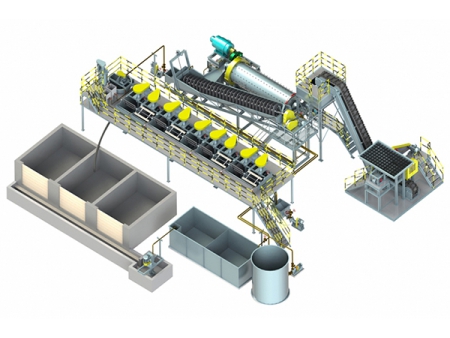

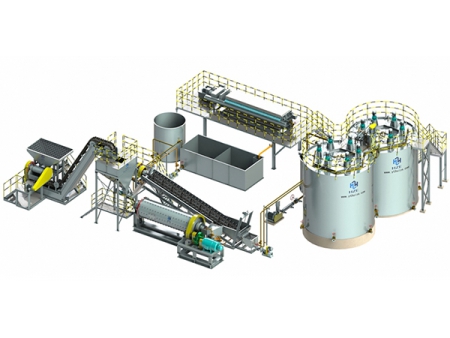

This gold gravity concentration plant is suitable for artisanal and small-scale mining (ASM) to recover high-grade gold grains from quartz veins or other raw ores. With a simple structure, the mini gravity concentration plant is not only easy to operate and carry but aslo cpsts a low price. This plant ensures a satisfacotry gold revocery ratio.

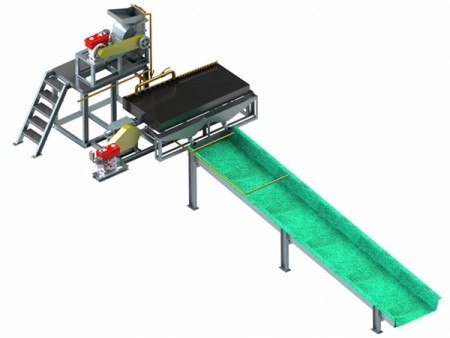

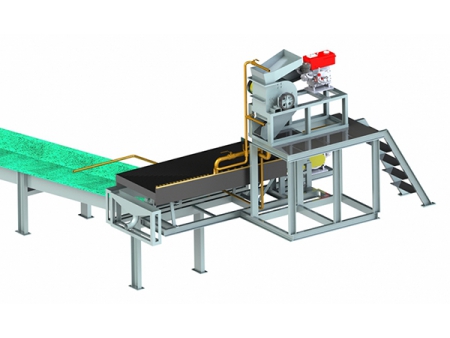

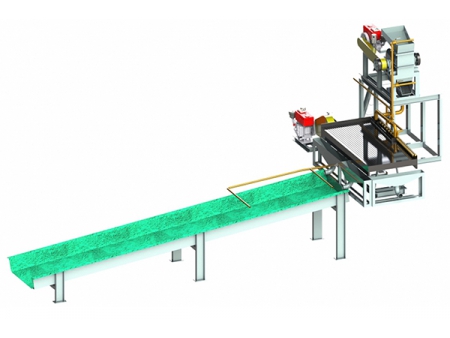

The diesel-driven hammer sand blaster is installed on the steel frame. The main working component of this sand blasting equipment is a rotor embedded with hammer. The rotor is composed of main shaft, disc, pin roll and hammer. Motor-driven rotor rotates at high speed in the crushing region where the rocks of -50mm and water are fed in and comminuted by the blowing, smashing, cuttin,g and grinding of the hammer. Under the rotor, there is a sieve plate which discharges the undersize particles and water. The coarse oversize particles are held on the sieve plate and receives further crushing and grinding by the hammers. Finally the qualified undersize particles are discharged out of the crushing region.

The shaking table is adopted to recover gold and the chute continues to recover gold remaining in tailings.

The mineral processing of the diesel-driven shaking table is carried out on the table covered with a series of wave grooves (protruding rubber bands perpendicular to the side of the feed pipe). The ore particles enter the table through the feed pipe and the feed water tank provides a transverse flow of water at the same time. Under the gravity, transverse water force and the inertia and friction force generated by the reciprocating and asymmetric motion of the table, the ore particles are stratified according to specific gravity and particle size and move longitudinally along the table and transversely along the inclined table. Therefore, the particles with different gravity and particle sizes gradually fan-flow down from side A to side B along their respective moving direction, then are discharged from different areas of the concentrate side and tailings side respectively and sorted into concentrate, middling and tailings.

The shaking table possesses high benefication ratio and concentration efficiency. It is easy to operate and adjust.

Since the grade of gold grains in the chute is relatively low, a shaking table can be used to beneficiate these grains and make them concentrates that can also be beneficiated for direct melting by shaking table for fine screening. By the use of cyanidation or amalgamation after the grinding of these tailings, gold can be recovered.

| Capacity (kg/h) | Raw Ores Size (mm) | Comminution Size (mm) | Power (HP) | Recovery Ratio (%) | Table Area (m2) |

| 500 | -50 | -1.8 | 26 | >70 | 1.95 |