Small Scale Relocatable Modular Gold Flotation Plant

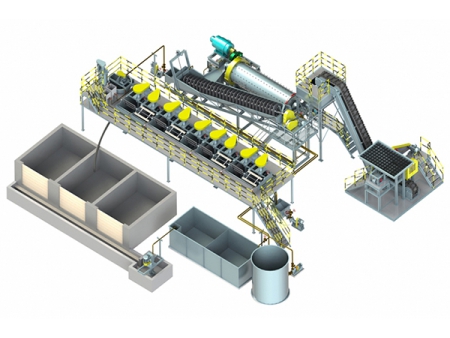

Relocatable Modular Flotation Plant is suitable for recovering gold from sulphide ores. The concentrate produced by flotation is ready for next cyanide leaching.

The flotation plant can be operated as an individual pilot scale plant.

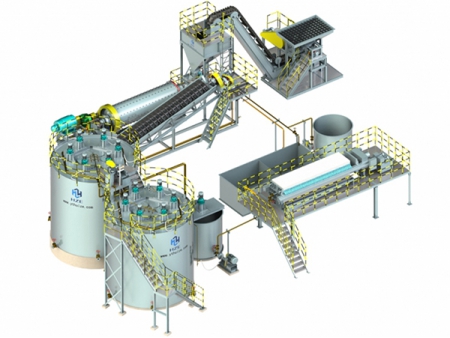

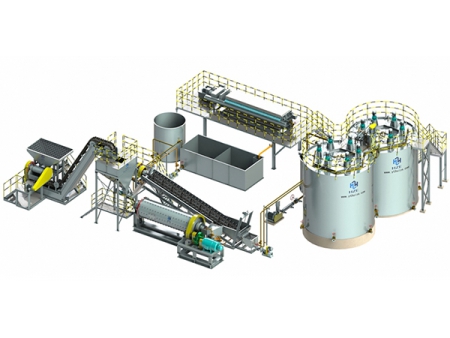

According to the properties of raw materials and the demands of clients, the gravity concentration plant is usually composed of crushing module, grinding and classification unit, gravity concentration module, water supply module and power supply module to maximize the recovery ratio.

Rocks are crushed to the particle size suitable for grinding and the module consists of composed of hopper, crusher, belt conveyor, ore feeder.

The crushing of ore is usually two-stage. The first crusher can be placed in the mining area ( driven by a diesel engine) or the processing plant.

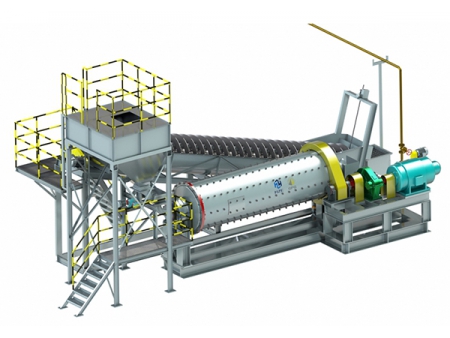

The closed-circuit grinding and classification system consisting of the ball mill and spiral classifier can dissociate ore into particles suitable for recovery. The module can be adjusted to a closed-circuit system consisting of the ball mill, slurry pump and hydrocyclone according to customers' needs.

The grinding and classification unit is completely set on a steel frame.

The water supply module is composed of the water tank, water pump and water supply pipeline. This module can fully control the use ratio of water, achieving ideal water balance.

It is composed of the diesel generator, the electrical distribution device and the electrical starter panel, which is suitable for areas that are hard to get to and has difficulties in power supply.

Note:

If ores contain a few gold particles, we suggest using gravity concentration module to cooperate with flotation module to maximize the recovery ratio. The concentrate produced by gravity concentration and flotation can be melted individually or separately.

If ores also contain oxidized ores, we advise small scale processing plants to adopt carbon-in-pulp and carbon-in-leach processing.

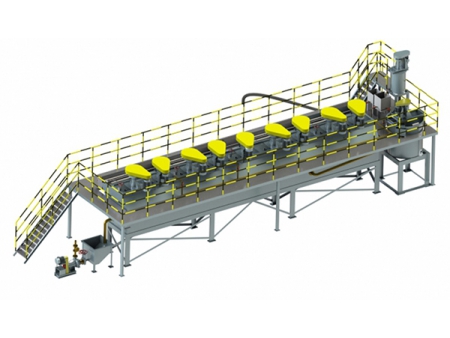

This module is composed of slurry mixing tank, reagents preparation tank and flotation machine. Chemical reagents are transformed into solutions in reagents preparation tank and the slurry and the reagent solutions are perfectly mixed in the slurry mixing tank. Then slurry flows to a series of closed-circuit flotation machines for concentrate production. Those machines work for coarse flotation, fine flotation and scavenging, leading to a high recovery rate.

Concentrate slurry naturally flows into a set of sedimentation tanks for natural sedimentation and the obtained clear water will be recycled. Concentrate after sedimentation are collected for cyanide leaching.

This type of flotation machine can absorb a large amount of air with low power consumption.Each flotation cell possesses triple functions of self-aspiration of air, self-aspiration of slurry and flotation. A couple of flotation machines are interconnected to form flotation circuits without any aiding equipments and all the tanks are distributed horizontally. The combination of flotation machines can adjust flotation phase and each phase's tank numbers according to the changes of ores at any time, achieving the best flotation quality.

The unloading side of each flotation cell is installed with a adjusting device which is convenient for regulating slurry level. Both sides of the impeller are installed with backward-inclined blades which are able to produce a good slurry circuit and avoid coarse sand deposits.

As the impeller rotates, a vacumm region is formed in the interval between impeller and rotor. Under this circumstance, air and slurry are sucked into this vaccum region for combination. The combination (froth) attached with valuable mineral particles will rise upward and gold can be recovered.

| Model parameter | HZF-1 | HZF-2 | HZF-3 | HZF-5 |

| Capacity(t/h) | 1 | 2 | 3 | 5 |

| Inlet sizeD80(mm) | 18 | 18 | 18 | 18 |

| Grinding size (mesh) | 150 | 150 | 150 | 150 |

| Ambient temperature(℃) | -15~45 | -15~45 | -15~45 | -15~45 |

| Gold recovery(%) | >92 | >92 | >92 | >92 |