Continuous Asphalt Mixing Plant

Request a Quote

Energy Saving

- Continuous asphalt mixing plant eliminates the need for hot aggregate screening, storage and weighing, the continuous asphalt production process is therefore simplified compared to the batch process.

- Since there is no filler elevator, vibrating screen, electric hoist, hot aggregate bin, hot aggregate weighing scale, the total power of the plant is reduced by approximately 15% (50% less power of aggregate elevator and 30% less power of air compressor).

- No waste of aggregates.

Environmental Protection

- Less dust particles are produced.

- Lower fuel consumption of burner leads to reduced exhaust gas emissions.

High Quality Finished Product

- Aggregate gradation control system efficiently avoids the gradation error that may occur during secondary screening.

- Constant temperature control can be achieved since there is no cooling process. The difference of recycled mix discharge temperature and mix temperature is small, enabling the temperature of mixing process to be easily controlled.

- With very low levels of oxygen during the asphalt mixing process, oxidative aging of asphalt can be efficiently controlled.

Key Technologies

- Aggregate Weighing

- TTM patented technology for precise continuous weighing of aggregates.

- The control system automatically adjusts the asphalt flow according to the aggregate flow and specified proportion, thus ensuring the precise control of the required proportions.

- The weigh scale is automatically calibrated.

- The dynamic weighing accuracy can reach ±1.5.

Bitumen Weighing

TTM patented technology allows for bitumen weighing scale calibration when equipment is running, providing high efficiency without affecting the operation of the equipment.

Filler Weighing

TTM patented technology allows for filler weighing scale calibration when equipment is running, providing high efficiency without affecting the operation of the equipment.

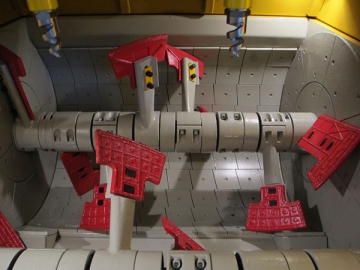

- Homogeneous Mixing

- Two twin-shaft paddle mixers are used, providing long mixing time.

- The opening angle of the discharge door is adjustable.

- Specially arranged paddles offer high flexibility allowing for quick adjustment according to the properties of the materials.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos