Robotic Palletizing System

Request a Quote

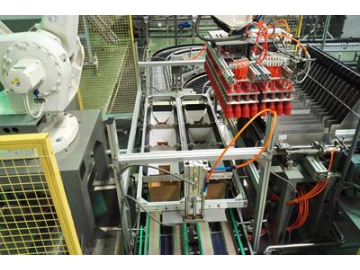

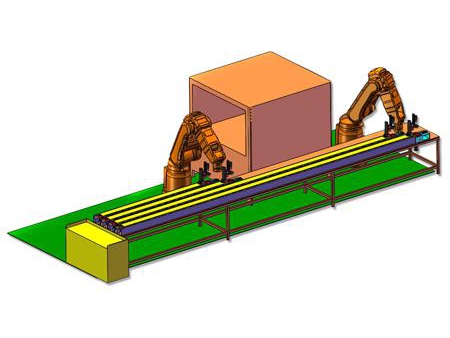

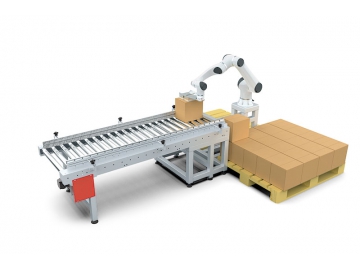

The robotic palletizing system can be divided into single-row palletizing machines, low-level palletizers, and high-level palletizers. We can provide you with the most suitable robot palletizing machine according to your needs. Please contact us.

SpecificationYCMD-25R single-row palletizing machine

| Dimension | (L)8000MM×(W)4500MM×(H)3000MM |

| Maximum load per floor | 180KG |

| Maximum load per pallet | 1600KG |

| Maximum stacking height | 1650mm (With pallet height) |

| Air consumption | 500NL/MIN |

| Power supply/power | 3 phase 5line, AC 380V/50HZ, 15KW |

| Machine weight | 4500KG |

| Dimension | (L)8000MM×(W)4500MM×(H)3000MM |

| Maximum load per floor | 240KG |

| Maximum load per pallet | 1600KG |

| Maximum stacking height | 1650mm (with pallet height) |

| Air consumption | 500NL/MIN |

| Power supply/power | 3 phase 5line, AC 380V/50HZ, 15KW |

| Machine weight | 4500KG |

| Dimension | (L)8000MM×(W)4500MM×(H)3000MM |

| Maximum load per floor | 450KG |

| Maximum load per pallet | 1600KG |

| Maximum stacking height | 1650mm (with pallet height) |

| Air consumption | 500NL/MIN |

| Power supply/power | 3 phase 5 line, AC 380V/50HZ, 15KW |

| Machine weight | 4500KG |

- A robot with a powerful computing function can perform high-precision operations and achieve rapid packing, stacking and unstacking.

- Robotic palletizing machines for packing, stacking and unstacking can be flexibly laid out in a production line. Our robotic palletizing machine can palletize two or more lines at the same time, which is an ideal option for palletizing at the end of the production line.

- Using top quality products such as servo motor, programmable controllers, and variable frequency speed controllers, we can ensure the system hardware is reliable with a long service life.

- High-quality hardware is combined with specialized control software designed by experts, which achieves a high automation system. Protection for equipment and operators can be provided by perfect safety interlocking mechanisms.

- The level of factory automation can be improved with advanced technology, stable and high quality products and perfect services.

When it comes to secondary packaging equipment, Beijing YCTD Packaging Machinery Co. is king! First established in Beijing in 2001, YCTD specializes in the design and production of equipment used to wrap beverages after their initial packaging. With nearly 2 decades of experience, we have become a leading packaging solutions provider, working with some of the largest beverage producers in the world. Some of our partners include, Huiyuan Group, Coca-Cola, Pepsi, Dali Group, Wanglaoji, Cestbon, Ganten, Uni-President Group, and Master Kong. Our main series of products is made up of heat shrinkable packaging machines, case erector packers, stacking systems, and conveying systems. Quality is what drives us forward and we have built a company strategy around delivering quality products and services to our valued customers.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos