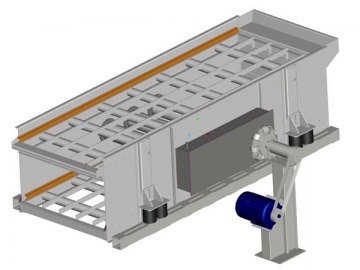

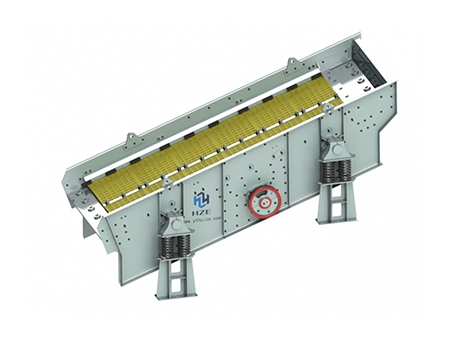

Vibrating Feeder (Suspended Type)

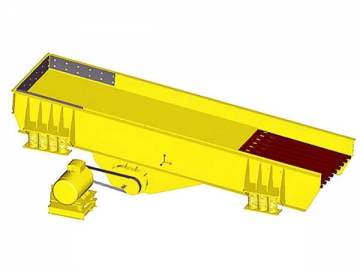

The suspended type vibrating feeder supports installation inclination angle of 15 degrees, and is designed for feeding materials with size less than 500mm. The feeding equipment offers maximum feeding capacity of 600t/h.

Product Application

The GZG series vibrating feeder (suspended type) is designed to be used for the continuous feeding of coarse and fine aggregate materials into a material crusher in order to increase its working capacity. Using its built in screening grills, the vibratory feeder can filter out materials that the operator does not want to enter the rock crusher. This feeder system is often used for the crushing and screening processes for quarries, mines, and building projects.

Main Features of the Suspended Type Vibrating Feeder

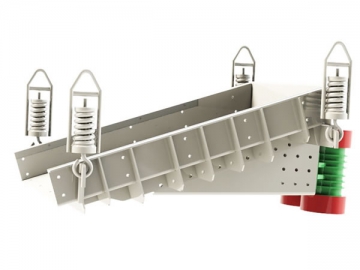

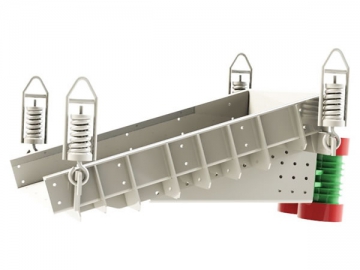

- Vibration motor

- Screening grilles

- Side protection panels

1. The vibrating feeder (suspended type) features easy installation and maintenance due to its simple design and light weight

2. Equipped with an efficient vibration motor, the GZG series vibrating feeder can maintain smooth operation and low working noise.

3. The adjustable exciting force, allows the operator to control the feeding capacity.

4. The durable chute greatly extends the working life of the material feeder.

5. Stable excitation force ensures reliable material feeding without clogging.

6. Vibrating feeders with sealed structure design are available, upon request. They can effectively prevent dust pollution and thus are more environmental friendly.

Main Technical Parameters of the Vibrating Feeder

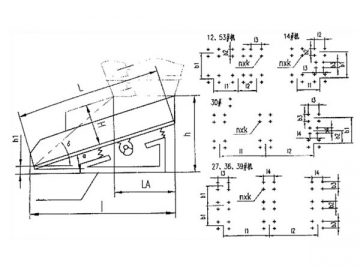

| Model | Chute Size (mm) | Max. Feeding Size (mm) | Capacity (TPH) | Motor Power (kw) | Motor Voltage (v) | Installation Angle | Basic Weight (kg) |

| 1000×1800 | 350 | 350 | 1.5×2 | 380 | 0-15° | 2960 | |

| 1200×1800 | 350 | 400 | 1.5×2 | 380 | 0-15° | 3260 | |

| 1400×2200 | 500 | 600 | 2.4×2 | 380 | 0-15° | 3875 |