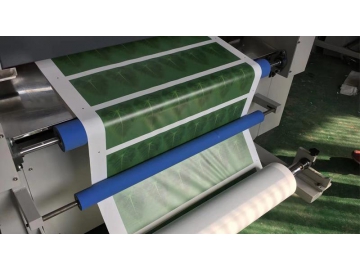

Infrared Drying Tunnel (IR Dryer)

Infrared paint curing system for drying coatings on workpieces

The infrared drying tunnel is an essential equipment in modern coating processes. It's suitable for the post-application phase of roll coating, spray coating, and curtain coating. This drying machine specializes in efficiently volatilizing diluents and bubbles from the surface coating, ensuring a smooth and even finish before proceeding to the drying stage. It effectively handles the critical task of preparing the coated surface for final drying and curing, making it a vital component in achieving high-quality finishes.

| Model | Working width (mm) | Working thickness (mm) | Min. working length (mm) | Feeding speed (m/min) | Drying temperature (℃) |

| 600 | 2-80 | 500 | 0-10 | 0-300 | |

| 900 | 2-80 | 500 | 0-10 | 0-300 | |

| 1300 | 2-80 | 500 | 0-10 | 0-300 | |

| 1650 | 2-80 | 500 | 0-10 | 0-300 | |

| 1950 | 2-80 | 500 | 0-10 | 0-300 | |

| 2200 | 2-80 | 500 | 0-10 | 0-300 | |

| 2400 | 2-80 | 500 | 0-10 | 0-300 | |

| 2600 | 2-80 | 500 | 0-10 | 0-300 |

Note: The length of the equipment can be customized to meet specific process requirements.

After undergoing coating processes, products pass through a temperature-controlled, constant-temperature tunnel. As they enter the initial phase of the tunnel, diluents and bubbles in the coating are volatilized, leading to a leveled surface. In the latter phase, the products are subjected to higher temperatures (or pass through a UV curing machine), ensuring thorough drying (or curing). This comprehensive process guarantees a superior finish, enhancing both the appearance and durability of the coated products.