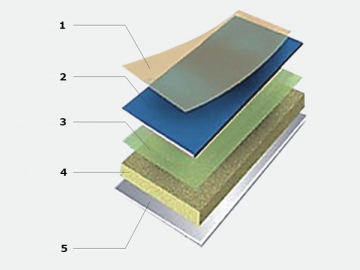

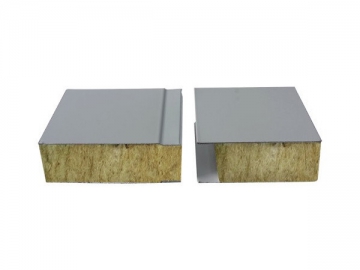

Polyurethane Sandwich Panel

1. Protective film

2. Color steel plate

3. High strength adhesive layer

4. Non-combustible sandwich layer materials(EPS)

5. Color steel plate

Introduction

The polyurethane sandwich panel takes the polyurethane as sandwich material. It shares the same characteristics of EPS sandwich panel. In addition, the PU sandwich panel possesses the feature of being nonflammable and a wide range of service temperatures. The service temperature of the sandwich material ranges from -196℃ to 130℃. The instant temperature can be 200℃.

When used in low temperature environment, the PU sandwich panel shows slight shrinkage and no tendency of embrittlement. Therefore, it is the ideal thermal insulation material for cryogenic projects. The polyurethane sandwich panel also has the advantages of being of non-toxic, non-corrosive, and stable in heat conductivity. It is widely used as roof panel, wall panel, ceiling panel and partition wall of steel framed workshop and prefabricated house.

Specification

Steel thickness: 0.3mm-0.7mm;

Sandwich thickness: 50mm-250mm

Width: 950mm, 1150mm

Length: can be customized

Characteristics

1. Light weight. The weight per square meter is only 10-14 kg.

2. Excellent thermal insulation performance. Thermal conductivity: λ=0.0175 KW/m.h.℃. Fireproofing Grade: B1, B2.

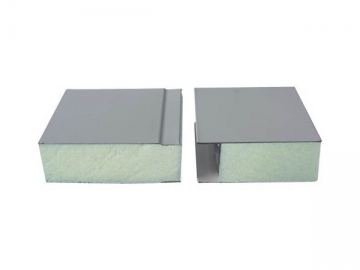

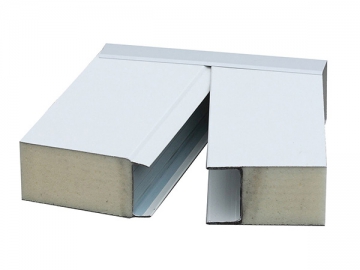

3. The connection is reasonable and convenient:

a. the panel adopts two buckles for the connection, avoiding the leakage from the roof, and save the use of fittings.

b. the panel adopts the male and female sides for the joint, which is good-looking, and easy to install. It also saves the fittings.

| Item | Unit | Index of Properties | |||||

| Ⅰ | Ⅱ | ||||||

| A | B | A | B | ||||

| Density ≥ | kg/m2 | 30 | 30 | 30.0 | 30 | ||

| Compression strength (Compressive stress under 10% deformation) ≥ | kPa | 100 | 100 | 100 | 150 | ||

| Thermal conductivity coefficient ≤ | w/(m.k) | 0.022 | 0.027 | 0.022 | 0.027 | ||

| RH Water vapor permeability coefficient ( 23 2) ℃ /0% to 85%RH ≤ | ng/Pa.m.s | 6.5 | 6.5 | ||||

| Water absorbing capacity ≤ | % | 4 | 3 | ||||

| Flammability | grade Ⅰ | Vertical Combustion | Average Burning Time (S) | 30 | 30 | ||

| 250 | 250 | ||||||

| grade Ⅱ | Level Combustion | Average burning time(S) | 90 | 90 | |||

| Average burning intensity ( mm) | 50 | 50 | |||||

Note:

Class Ⅰ: does not load.

Class Ⅱ: bears load.

Class Ⅲ: bears heavy load.