Brominated Flame Retardant

Brominated flame retardant is the most widely used flame retardant due to its outstanding flame retardance. The decomposition temperature of most brominated flame retardant is 200-300℃, matches the decomposition temperature of most polymers. Thus, it can play a flame retardant effect at the best time, when the gas phase is the same as the condensation, and the flame retardant efficiency is high.

Meanwhile, this kind of flame retardant has good compatibility with resin and has little effect on the mechanical properties of the composites.

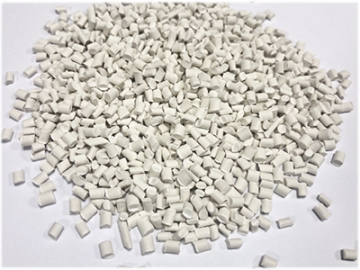

PBT-X-18M is a special bromine antimony flame retardant masterbatch for PBT, made by melting, blending and granulating with imported new material toughening agent as the carrier, brominated epoxy and antimony trioxide as the main raw materials.

It's a special flame retardant for GF reinforced PBT, which has passed the UL94- V0 standard, and did not migrate or precipitate. This flame retardant masterbatch has excellent compatibility with PBT and can be evenly dispersed in PBT with excellent flame retardant performance. Compared with its bromine-based flame retardant system, the mechanical properties of PBT-X-18M have no significant difference. In short, PBT-X-18M has the characteristics of eco-friendly, good flame retardant effect, and excellent water resistance.

FR-DBDPE is a new, high efficiency, low additive and eco-friendly flame retardant used widely. It has high bromine content, good thermal stability, good UV resistance and lower exudation than other bromine flame retardants. It is suitable for producing flame retardant materials for various applications including computers, fax machines, telephones, copiers, household appliances, etc. It is quite stable in the used system, and the thermoplastic with it can be used repeatedly.

Compared to the conventional flame retardant DBDPO, DBDPE has a less adverse effect on the performance of flame retardant materials and has better light resistance and lower exudation.

| Index Item | ||

| CAS | 7789-61-9 | 84852-53-9 |

| Bromine content | ≥80% | ≥80% |

| Appearance | White granule | White powder |

| Density | 1.6-1.8 g/cm3 | 2.817 g/cm3 |

| Whiteness | ≥ 90% | ≥ 88% |

| Moisture content | ≤ 0.1% | ≤ 0.1% |

| Particle Size | -- | 3µm |

| Melting point | ≥280℃ | ≥ 345℃ |

| Application | PBT | HIPS, LDPE, ABS, PVC, PP, PBT, etc. |

- High bromine content and excellent thermal stability, suitable for higher processing temperatures.

- Odorless, strong UV resistance and low toxicity.

- Slightly soluble in alcohol, ether, almost insoluble in water.

- PBT-X-18 fire retardant masterbatch can be directly mixed with PBT to process the finished product, which improves convenience, simplifies production process without dust pollution, and saving cost.

Note: If you do not see a flame retardant solution here that meets your needs, we offer customization solutions according to your particular needs.