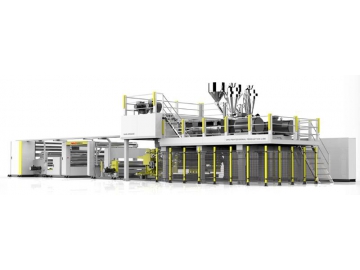

High Efficiency Poreless Tablet Coating Machine

As a piece of beautiful, efficient, energy-saving, safe and easy-to-clean electromechanical integration equipment, the high efficiency poreless tablet coating machine is widely used to make organic film, water soluble film, sustained-release and controlled-release coatings, and sugar coating for tablets, pills, pellets, watered pill, dripping pill, granule pills and candies in pharmacy, biology, food and other fields. Negative pressure, temperature and other technological parameters can be automatically controlled by PLC, which is very convenient. The main machine, hot air cabinet, exhaust cabinet, thermostatic mixing drum and cleaning system are all made by high-quality imported stainless steel, meeting the requirement of GMP. In addition, this high efficiency poreless tablet coating machine has passed EU CE certification.

Compared with the pored tablet coating machine, this high efficiency poreless tablet coating machine is applicable to a broader range, saves more energy and auxiliary materials, and is easier to clean. The coating drum adopts a poreless structure and is completely enclosed. The guide plate inside the drum enables tablet cores to move freely, preventing fragments and cracked edges. In addition, the drum wall and guide plates are processed by mirror polishing, improving the yield.

Specifications| Item \ Model | |||||

| Load Capacity | 300kg/batch | 150kg/batch | 80kg/batch | 40kg/batch | |

| Rotation Speed of Coating Drum | 1-13RPM | 1-16RPM | 1-19RPM | 1-21RPM | |

| Diameter of Coating Drum | 1500mm | 1280mm | 1006mm | 825mm | |

| Motor Power of Air Exhaust Cabinet | 7.5kw | 5.5kw | 3kw | 2.2kw | |

| Flow of Air Exhaust Fan | 10000m³/h | 7419m³/h | 5266m³/h | 3517m³/h | |

| Motor Power of Hot Air Cabinet | 2.2kw | 1.5kw | 1.1kw | 0.75kw | |

| Flow of Hot Air Fan | 3517m³/h | 2356m³/h | 1685m³/h | 1285m³/h | |

| Diameter of Feed Inlet | 475mm | 458mm | 380mm | 340mm | |

| Main machine Power | 3kw | 2.2kw | 1.5kw | 0.75kw | |

| Weight of Main Machine | 1200kg | 1000kg | 800kg | 550kg | |

| Dimensions of the Hot Air Cabinet | 900×800×2280mm | 970×1150×2170mm | 1040×920×2170mm | 900×800×1500mm | |

| Dimensions of Air Exhaust Cabinet | 1050×1050×2100mm | 1040×1340×2060mm | 900×820×1850mm | 820×720×1750mm | |

| Host Volume (L×W×H) | 1720*1600*2120mm | 1450*1350*2100mm | 1300*1040*1920mm | 1000*1380*1540mm | |

| Clean Air | Pressure | >0.4Mpa | >0.4Mpa | >0.4Mpa | ≥0.4Mpa |

| Air Consumption | 1.1m³/min | 0.7m³/min | 0.35m³/min | 0.15m³/min | |

The inhaled air is filtered to reach the purification level of 10862,42000. Exhaust uses a bag filter and the dedusting effect is up to 99%. The fan-shaped wind paddle can be either air inlet or outlet and aperture of the wind paddle ranges from 0.6mm to 3mm, applying to coatings of different specifications. Materials during working can be seen clearly through the explosion-proof lamp inside the coating drum, facilitating control of technology change.

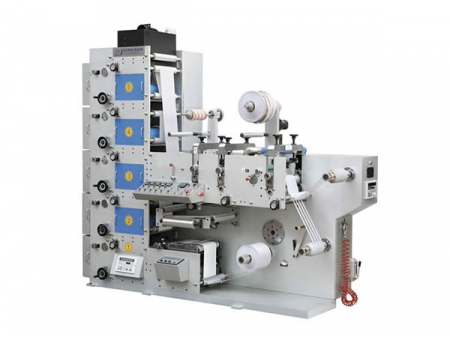

Iwata Spray Guns

Iwata Spray Guns Fan Shaped Propeller

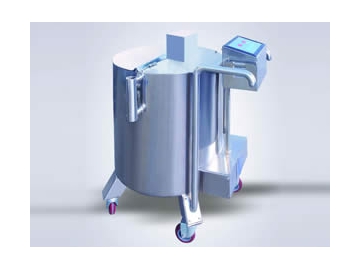

Fan Shaped Propeller Peristaltic Pump

Peristaltic Pump

Jiangnan Enterprise is a professional high efficiency poreless tablet coating machine manufacturer in China. The wide range of products we offer includes high efficiency tablet coating machine, high efficiency laboratory tablet coating machine, automatic capsule filling machine, and more.