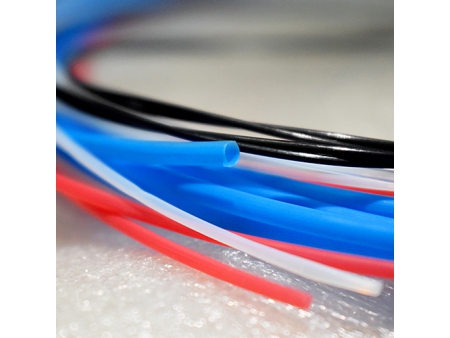

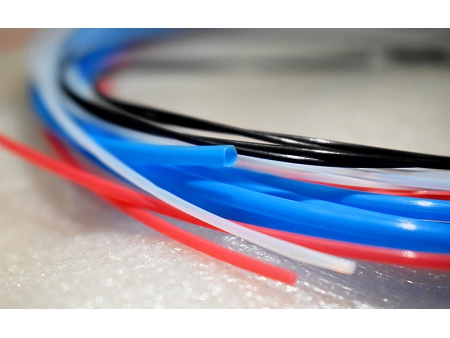

Engineering Plastic Gear Cable Liner Tube

Request a Quote

CYG-AMT

- Typical working temperature: -50°C to 200°C

- Low friction coefficient, high abrasion resistance, long service life

- Ideal mechanical properties and chemical resistance

- Long lengths (e.g., Ø3.7×4.5 with continuous length up to 1500 M)

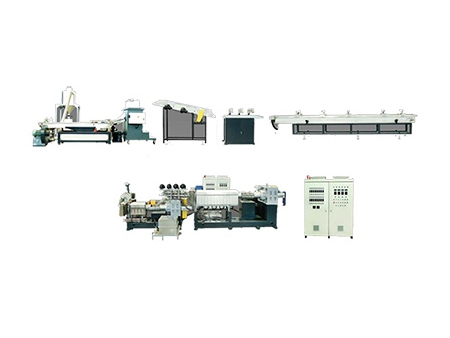

- Traceable tubing (proprietary equipment)

Applications

- Our PTFE gear cable liner tube is a wear-resistant fluoroplastic liner tube manufactured using high-quality PTFE dispersion resin.

- It exhibits a low friction coefficient (approximately 0.02) and high abrasion resistance. Our tube is primarily used in various automotive applications, including car, bus, truck, forklift, mining engineering vehicles, yachts, and other operational cable assemblies.

| Properties | Test Method | Performance | ||

| CYG-AMT(G) | CYG-AMT(M01) | CYG-AMT(M02) | ||

| Base material | - | PTFE | PTFE | PTFE |

| Filler | - | None | Abrasion resistant filler | High temperature abrasion resistant resin |

| Color | - | Natural | Brown | Yellow |

| Specific gravity | ASTMD792 | 2.13g/cm³ ~2.20g/cm³ | 2.0g/cm³ ~2.16g/cm³ | 2.0g/cm³~2.16g/cm³ |

| Melting point | ASTMD3418 | 327℃±10℃ | PTFE: 327℃±10℃ Filler: 280℃±10℃ | PTFE: 327℃±10℃ Filler degrade>450℃ |

| Continuous operating temperature | - | 200℃ | 200℃ | 200℃ |

| Tensile strength | ASTMD638 | ≥20.7MPa | ≥27.6MPa | ≥25.0MPa |

| Ultimate elongation | ASTMD638 | ≥200% | ≥150% | ≥150% |

| Wear resistance (self-developed test device) | Load: 80N R=400mm | - | ≥500000 cycles No crack, no breakdown | ≥1000000 cycles No crack, no breakdown |

| Chemical resistance | - | Excellent | Excellent | Excellent |

| Flammability | UL224 | Pass | Pass | Pass |

- Inner liner: PTFE/modified PTFE

- Outer layer: engineering plastics such as PA, PBT, or

- Low friction coefficient, high abrasion resistance, and long service life

- Competitive pricing with low noise and lightweight

Applications

- Our engineering plastic gear cable liner tube is an ideal choice for automotive cable assemblies. With its PTFE inner liner and engineering plastic outer layer, it meets the demand for low friction and high abrasion resistance while providing cost advantages. It finds wide applications in cars, buses, trucks, forklifts, mining vehicles, yachts, and other operational cable assemblies.

Features

- Low friction coefficient, high abrasion resistance, and long service life

- Competitive pricing with low noise and lightweight

- Long lengths (e.g., continuous length up to 1500 M for Ø3.7×4.5)

- Traceable tubing (proprietary equipment)

- Material options and customizable specifications

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos