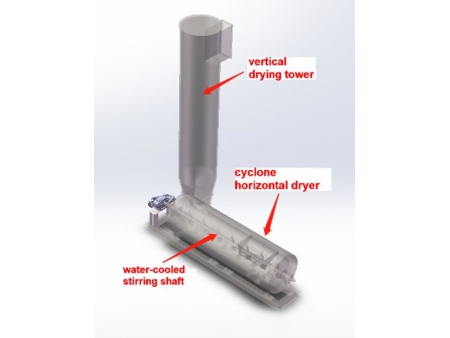

Circulating Fluidized Bed Boiler

Rated steam output: 35-130t/h

Rated working pressure: 3.8-5.3Mpa

Rated steam temperature: 450℃

Fuel type: coal, biomass, semi-coke, city rubbish, industrial waste, desulfurization agent, slag, gangue and shale oil

The circulating fluidized bed boiler is used primarily to provide thermal energy to thermal power plants, as well as energy for central heating, gas supply, and city or business heating systems. Suitable fuel types for use in the boiler include different coal types, industrial waste and biomass. Due to volume and transportation limitations, we ship the boiler unassembled to the customer, and it is the customer’s responsibility to assemble it on site. We will send technicians to provide on-site installation and debugging services upon client request.

| Type | Rated steam output ( t/h ) | Rated working pressure ( MPa ) | Rated steam temperature ( ℃ ) | water supply temperature ( ℃ ) | Design emission temperature ( ℃ ) | Elevation of cylinder center ( mm ) | Elevation of running section ( mm ) | Central width of left and right columns of boiler ( mm ) | Central depth of front and back columns of boiler ( mm ) |

| 35 | 3.82 | 450 | 104 | 140 | 25150 | 7000 | 4650 | 11200 | |

| 45 | 3.82 | 450 | 104 | 132 | 27150 | 7000 | 5000 | 11600 | |

| 75 | 3.82 | 450 | 150 | 145 | 31850 | 7000 | 6800 | 12700 | |

| 100 | 3.82 | 450 | 150 | 145 | 34490 | 7000 | 6800 | 13700 | |

| 130 | 5.3 | 450 | 150 | 140 | 39000 | 8000 | 9700 | 19480 |

The steam boiler features complex processing links, with fine processing an important factor in determining the product quality and safe usage.

1. Boiler material: seamless steel pipe

2. Welding process: Argon arc welding and radiographic testing

3. Bending shaping: the tube is shaped after the bending process (done inside the pipe bending machine) in order to ensure the accuracy of the coil’s outline dimension, and that it satisfies GB/T17410 standards.

4. Water pressure testing: after shaping, the water pressure test for the boiler tube is carried out before the boiler leaves the factory.