IQF Fluidized Bed Freezer

SLD Series

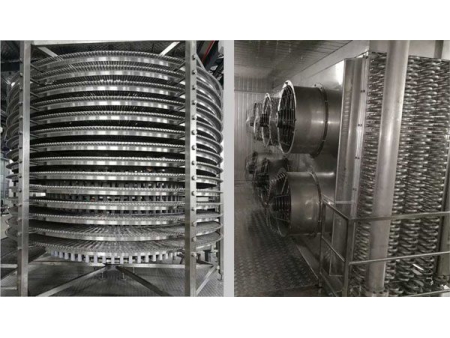

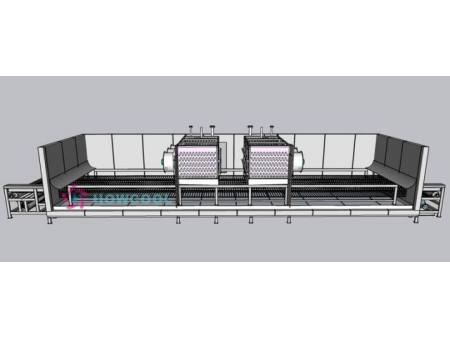

SLD type IQF fluidized bed freezer is an advanced freezing machine developed by our company, incorporating cutting-edge technologies from countries like Sweden, the United States, and Canada. It offers practicality and efficiency while ensuring a real fluidized IQF effect. It is particularly well-suited for freezing granular and short strip-shaped fruits and vegetables.

- The material conveyor of this IQF freezer adopts a two-stage structure. Both the conveyor speed and fan speed of the first freezing stage and deep freezing stage are independently adjustable to accommodate the processing needs of different materials.

- The first freezing stage is equipped with a bypass pulse device to enhance fluidization effect. Combined with a beating mechanism, it effectively prevents the agglomeration of fruits and vegetables, achieving quick freezing of materials.

- The quick-freezing machine is also equipped with an optional ADS (Air Defrosting System) automatic defrosting device. The ADS device maintains the frost layer thickness on the evaporator fins below 3mm for an extended period, ensuring continuous production for up to 20 hours.

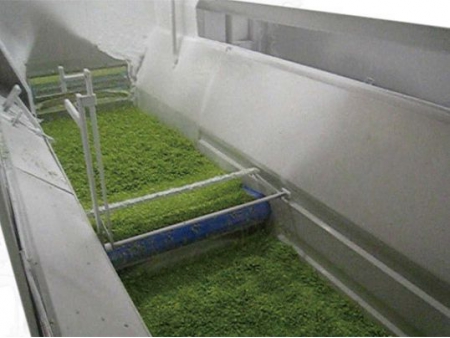

Fresh Green Bean

Fresh Green Bean Frozen Green Bean

Frozen Green Bean Fresh Sweet Corn

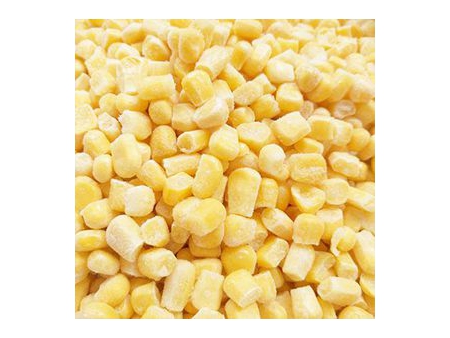

Fresh Sweet Corn Frozen Sweet Corn

Frozen Sweet Corn

| Model | |||||||

| Capacity (kg/h) | 500 | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 |

| Dimensions (m) | 7.2×3.8×3.8 | 8.2×4.4×3.8 | 10.2×4.4×3.8 | 11.2×4.4×3.8 | 13.2×4.7×4.4 | 16.2×4.7×4.4 | 20.2×4.7×4.4 |

| Freezer length (m) | 5 | 6 | 8 | 9 | 11 | 14 | 18 |

| Belt width (m) | 1 | 1.2 | 1.2 | 1.2 | 1.3 | 1.3 | 1.3 |

| Input material temperature (℃) | 15 | ||||||

| Output material temperature (℃) | -18 | ||||||

| Freezing temperature (℃) | -36 /-2 | ||||||

| Freezing time (min) | 5-50 (continually adjustable) | ||||||

| Refrigerants | R717/R507a/R404a | ||||||

| Cold consumption (kW) | 115 | 165 | 256 | 320 | 460 | 615 | 750 |

| Power (kW) | 28 | 42 | 57 | 66 | 99 | 105 | 129 |

Note:

1. Capacity mentioned above is based on green beans. The capacity may vary for different materials even with the same model.

2. Working conditions: 35°C/-40°C.

3. The power excludes the compressor system.

The evaporator adopts a three-inlet, three-outlet welding design to enhance refrigeration efficiency. The fins are designed with variable fin spacing to ensure continuous and efficient freezing.

High-efficiency centrifugal fans specifically designed for fluidization freezing are utilized. The fans have high air pressure and large air volume, capable of blowing even large frozen products. The fan also features lightweight blades, small starting current, and is designed with an anti-vibration structure.

A beating mechanism, with a triangular structure and made of wear-resistant and high-strength nylon material, is installed under the conveyor, and it is easy to replace. The beating mechanism works in combination with a high-volume and high-pressure fan to suspend the materials on the conveyor belt, thereby achieving individual quick freezing effect.

A loading belt cleaning and drying device is installed at the inlet, which has high air pressure and large air volume. It is capable of removing frost and impurities from the conveyor belt, thereby improving the quality of frozen products and meeting the requirements of food safety and hygiene.

The bottom of freezer is inclined on both sides, and each side is equipped with a small drainage ditch to maintain cleanliness and hygiene inside the freezer. This design meets the requirements of food safety and hygiene.

The use of 304 stainless steel air deflectors ensures uniform distribution of cold air, thereby improving the quality of the materials.