Commercial Vacuum Freeze Dryer / Lyophilizer

SFD-II Series

Commercial vacuum freeze dryer features an independent freezing tank, distinguishing it from the integrated form where freezing and drying take place in the same tank. This series of freeze dryer includes a pre-freezing system, drying tank, vacuum system, heating and cooling water or silicone oil system, refrigeration system, cold trap system, ice melting system, material transport system, automatic control system and remote monitoring system.

This lyophilizer is widely used for the rapid freezing and drying of vegetables, fruits, aquatic products, meats, seasonings, pasta products, biological products, beverages, and various agricultural products. It can also be applied in industries such as ceramics, chemicals, and graphene. The freeze drying equipment output can be customized based on the freeze-drying area, ranging from 0.5m² to 200m², greatly meeting the diverse production needs of different customers.

Recommendation Reason: Pilot & laboratory vacuum freeze dryer is a perfect fit for food processing enterprises that are seeking to new R&D products. The process curve obtained from this equipment can be easily applied to industrial production in large-scale equipment.

Specifications

| Model | ||

| Drying area | 0.5m² | 1m² |

| Tray size | 500×340×35mm | 750×340×35mm |

| Number of trays | 3pcs×2 | 4pcs×2 |

| Drying chamber size | Ø500×1400mm | Ø500×1750mm |

| Quick freezer size (L×W×H) | 1000×740×770mm | 1210×980×700mm |

| Overall dimensions (L×W×H) | 1900×1300×1800mm | 2600×1250×1800mm |

| Vacuum | 13.3-200 pa | |

| Heating plate temperature | Room temperature ~+120℃ | |

| Heating medium | Softened water | |

| Electrical heating | 2kW | 3kW |

| Cold consumption ( 35℃/-35℃) | 1.5kW | 2.4kW |

| Power | 8.5kW | 10.4kW |

Recommendation Reason: Production freeze dryer has a small footprint and is cost-effective, making it suitable for integrated teaching, research, and production in schools, as well as small-scale batch production for farmers and other similar operations.

Specifications

| Model | ||

| Drying area | 5.5m² | 10.4m² |

| Tray size | 540×635×35mm | 540×870×35mm |

| Number of trays | 16pcs×2 | 22pcs×2 |

| Drying chamber size | Ø1200×2300mm | Ø1600×2900mm |

| Quick freezer size (L×W×H) | 2800×970×1200mm | 2230×1850×2300mm |

| Overall dimensions (L×W×H) | 4400×2300×2000mm | 7400×2300×2400mm |

| Vacuum | 13.3~200pa | |

| Heating plate temperature | Room temperature ~+120℃ | |

| Heating medium | Softened water | |

| Electrical heating | 15kW | 24kW |

| Cold consumption ( 35℃/-35℃) | 11kW | 18kW |

| Power | 35kW | 63.2kW |

Recommendation Reason: SFD-II-25/SFD-II-50 Production freeze dryer features a medium-scale design and is ideal for applications involving high-value-added products.

Specifications

| Model | ||

| Drying area | 25m² | 50m² |

| Tray size | 540×635×35mm | |

| Number of trays | 72pcs×2 | 144pcs×2 |

| Drying chamber size | Ø1800×4400mm | Ø2400×4100mm |

| Quick freezer size (L×W×H) | 3000×2800×3000mm | 3800×3600×3600mm |

| Vacuum | 13.3-200pa | |

| Heating plate temperature | Room temperature ~+120℃ | |

| Heating medium | Softened water | |

| Electrical heating | 45kW | 96kW |

| Steam consumption (0.7mpa) | 70kg/h | 160kg/h |

| Cold consumption ( 35℃/-35℃) | 45kW | 110kW |

| Power | 64kW | 130kW |

Recommendation Reason: SFD-II-100/SFD-II-125 Production freeze dryer boasts the most popular production specifications both domestically and internationally, making it well-suited for large-scale and high-volume production in food processing enterprises.

Specifications

| Model | ||

| Drying area | 100m² | 125m² |

| Tray size | 540×635×35mm | |

| Number of trays | 288pcs×2 | 360pcs×2 |

| Drying chamber size | Ø2400×6800mm | Ø2400×8200mm |

| Quick freezer size (L×W×H) | 6000×3600×3600mm | 7400×3600×3600mm |

| Vacuum | 13.3-200pa | |

| Heating plate temperature | Room temperature ~+120℃ | |

| Heating medium | Softened water | |

| Steam consumption (0.7mpa) | 320kg/h | 400kg/h |

| Cold consumption ( 35℃/-35℃) | 180kW | 225kW |

| Power | 245kW | 287kW |

Recommendation Reason: SFD-II-200 Production freeze dryer is the only 200-square-meter freeze dryer in China that adopts a multi-cold trap system, offering high efficiency, energy savings, and convenient transportability.

Specifications

| Model | |

| Drying area | 200m² |

| Tray size | 540×635×35mm |

| Number of trays | 576pcs×2 |

| Drying chamber size | Ø2400×12300mm |

| Quick freezer size (L×W×H) | 11000×3600×3600mm |

| Vacuum | 13.3~200pa |

| Heating plate temperature | Room temperature ~+120℃ |

| Heating medium | Softened water |

| Steam consumption (0.7mpa) | 540kg/h |

| Cold consumption ( 35℃/-35℃) | 360kW |

| Power | 404kW |

The freeze dryer features an independent quick-freezing tank, allowing for the quick freezing of the next batch of products while processing in the freeze-drying tank. This reduces processing time per batch, thereby enhancing production efficiency.

Two sets vacuum maintaining systems are adopted, ensuring that production will not be affected by the failure of a single vacuum pump, thus preventing the scrapping of the entire batch due to pump malfunction.

The production equipment adopts one-step forming tray, ensuring hygiene without any dead corners and facilitating easy cleaning. This design complies with food safety and sanitation requirements. The trolley with anti-tray-slip rod are used to ensure stability during transportation and prevent slippage. The tray sizes range from 5m² to 200m², providing excellent versatility and uniformity.

The external multi-cold trap structure is adopted. This design eliminates the hygiene concerns associated with internal cold traps that are difficult to clean. Additionally, placing the cold trap above reduces the footprint and maximizes the utilization of the upper space in the workshop.

The refrigeration system adopts a parallel unit with multiple compressor heads, which can automatically adjust usage according to the load, greatly reducing production costs. The full-liquid supply uses the evaporator area effectively, maximizing heat exchange efficiency.

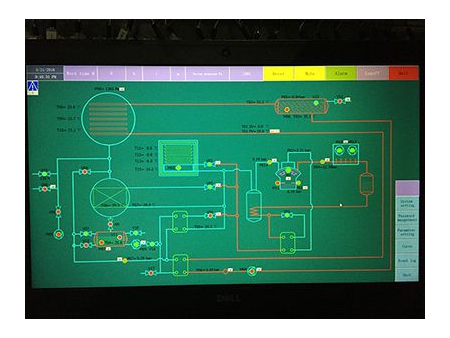

Our equipment is equipped with state-of-the-art instruments and meters from renowned international brands, ensuring high precision and exceptional quality. With the PLC PC control system, you can remotely monitor the production process and enjoy the added convenience of optional remote operation capabilities.

Heating plates utilize efficient radiation heating, ensuring uniform and even heat distribution across the materials. The internal circulation of hot water within the plates promotes optimal heat transfer efficiency. It also boasts excellent sealing properties, completely eliminating the risk of water leakage.