Automatic Capsule Filling Machine, CFK Series

The CFK series automatic capsule filling machine represents the latest advancement in fully automated capsule filling technology within our company. Throughout the research and development process, we have demonstrated bold innovation and conducted numerous experiments, resulting in the acquisition of nearly 20 patent certificates. In comparison to traditional models, the CFK series incorporates a modified transmission method, significantly enhancing equipment durability and operational stability.

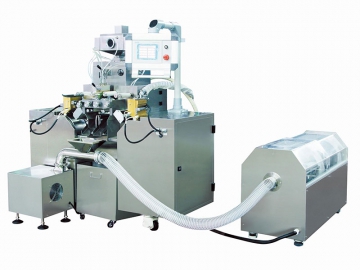

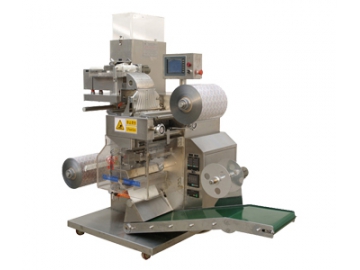

CFK series capsule filling machine is designed to accommodate the filling of both powder and granules into capsules ranging from 00# to 5# in size. To cater to diverse usage scenarios, users have the option to select additional auxiliary equipment such as automatic capsule feeding machines, vacuum loaders, metal detectors, polishing machines, and lifting machines.

-

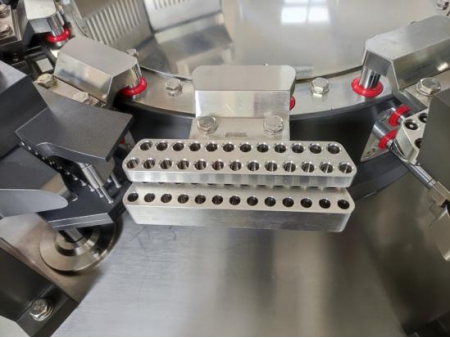

The filling process is accomplished by employing a tamping dosing method which accurately measures and fills materials while simultaneously eliminating waste capsules. The filling dosage can be fine-tuned by adjusting the punch lever.

-

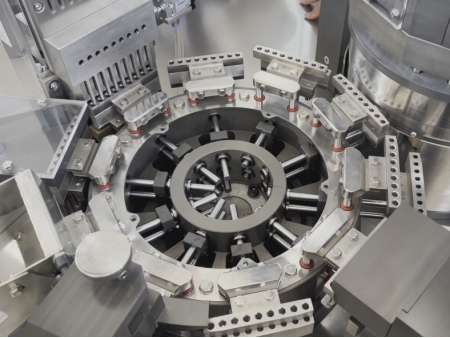

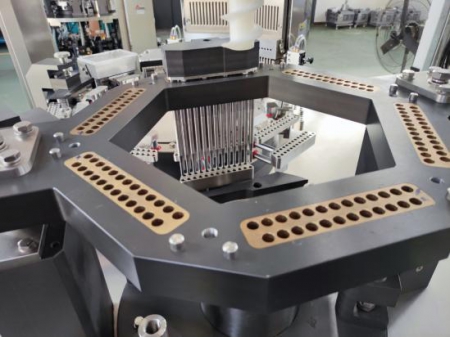

The most critical filling station utilizes an "inner cam" mechanism to achieve linear up and down motion. Compared to traditional "lever" driven mechanisms, this results in a more forceful filling action. The part is made of high-quality (38CrMoAl) special steel that is specifically designed for use in the internal groove wheel drive system. Additionally, it is equipped with imported Japanese coupling bearings, effectively avoiding the problems associated with traditional "lever" driven mechanisms, such as spring fatigue and fracture. This greatly improves the stability and service life of the machine.

-

The CFK capsule filling machine has replaced the previously suspended transmission device on the top of the main unit with a fixed transmission mechanism mounted on a reinforced base (30mm thick). This modification enhances the stability of machine operation and reduces maintenance time from the original 30 minutes to just 5 minutes, which is only 1/6 of the previous duration.

-

CFK series capsule filling machine features an added mold cleaning and blowing structure, which prevents the accumulation of dust on the molds. This significantly improves the loading efficiency of empty capsules and reduces the rate of capsule rejection. Additionally, the locking device is equipped with a cleaning function that effectively removes fine dust particles between the molds, ensuring that the capsule surfaces remain clean and smooth.

-

Compared to machines of the same type, CFK capsule filling machine excels in reducing material loss. The powder feeder is seamlessly connected to the equipment, eliminating the possibility of powder spillage into the workbench during feeding. The three-dimensional metering adjustment mechanism has undergone precise calculations, eliminating the natural deformation of the metering disc and copper ring.

-

CFK series capsule filling machine has redesigned the copper pad disc to fill the gap between the punch rod and the capsule body. This prevents the powder from falling and contaminating the workbench environment when the punch rod fails to accurately fill the material into the capsule body. As a result, the possibility of powder leakage is greatly reduced.

-

CFK series capsule filling machine integrates the original filling components into a single unit, evenly divided into six modules that are connected with screws. It takes about ten minutes to replace the mold.