Other Heat Exchangers

In stainless steel shell and tube heat exchangers, stainless steel is used in all components coming in to contact with corrosive media like heat exchanger tubes, cylinders and tube sheets. The standard material is 304/316L stainless steel. However, ferritic stainless steel, duplex steel and other special steels are employed depending on the environment and working conditions. These are regularly employed in reducing salts, inorganic acids, organic acids, alkalis, salts and other corrosive conditions.

TA2 pure titanium is a highly corrosion resistant material, used in a variety of settings where other metals may not stand up. From marine vessels to chemical and metallurgical industries, TA2 pure titanium components have proven to be an excellent choice for those who need protection from the corrosive qualities of brine, alkaline, acidic and neutral solutions. Heat exchanger tubes, cylinders and tube sheets constructed from TA2 pure titanium will stand up to penetrating elements, outperforming the corrosion resistance of traditional stainless steel and other non-ferrous metals.

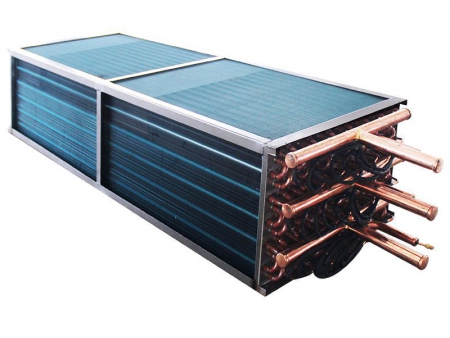

Copper is a popular choice for heat exchangers due to its impressive heat transfer capabilities and ease of processing. In the heat exchanger industry, the competitive price makes copper an excellent choice.

In stainless steel finned heat exchangers, stainless steel is used in all components coming in to contact with corrosive media like heat exchanger tubes, cylinders and tube sheets. The standard material is 304/316L stainless steel. However, ferritic stainless steel, duplex steel and other special steels are employed depending on the environment and working conditions. These are regularly employed in organic, flue, steam, and other gases.

| Model | Nominal heat exchange capacity kW | Water inlet/outlet inch | Refrigerant inlet inch | Refrigerant outlet inch | Length A mm | Width B mm | Height C mm | Weight kg | ||

| R22 | R134A | R407C | ||||||||

| | 176 | 141 | 158 | 3" | 1-3/8" | 2-1/8" | 2253 | 420 | 340 | 299 |

| | 193 | 155 | 174 | 3" | 1-3/8" | 2-1/8" | 2253 | 420 | 340 | 311 |

| | 211 | 169 | 190 | 3" | 1-3/8" | 3" | 2253 | 420 | 340 | 323 |

| | 229 | 183 | 206 | 3" | 1-3/8" | 3" | 2653 | 420 | 340 | 328 |

| | 246 | 197 | 222 | 4" | 1-5/8" | 3" | 2653 | 420 | 340 | 342 |

| | 264 | 211 | 237 | 4" | 1-5/8" | 3" | 2653 | 420 | 340 | 354 |

| | 281 | 225 | 253 | 4" | 1-5/8" | 3" | 2653 | 420 | 340 | 366 |

| | 299 | 239 | 269 | 4" | 1-5/8" | 3" | 2653 | 420 | 340 | 370 |

| | 317 | 253 | 285 | 4" | 1-5/8" | 4" | 2653 | 560 | 390 | 340 |

| | 334 | 267 | 301 | 4" | 1-5/8" | 4" | 2653 | 560 | 390 | 352 |

| | 352 | 281 | 317 | 4" | 1-5/8" | 4" | 2653 | 560 | 390 | 364 |

| | 369 | 295 | 332 | 5" | 1-5/8" | 4" | 2653 | 560 | 390 | 376 |

| | 387 | 309 | 348 | 5" | 1-5/8" | 4" | 2653 | 560 | 390 | 388 |

| | 404 | 324 | 364 | 5" | 1-5/8" | 4" | 2653 | 570 | 420 | 400 |

| | 422 | 338 | 380 | 5" | 1-5/8" | 4" | 2653 | 570 | 420 | 412 |

| | 440 | 352 | 396 | 5" | 1-5/8" | 4" | 2653 | 570 | 420 | 424 |

| | 457 | 366 | 411 | 5" | 1-5/8" | 4" | 2653 | 570 | 420 | 436 |

| 404 | 324 | 364 | 5" | 1-5/8" | 4" | 2653 | 570 | 420 | 432 | |

| 422 | 338 | 380 | 5" | 1-5/8" | 4" | 2653 | 570 | 420 | 447 | |

| 440 | 352 | 396 | 5" | 1-5/8" | 4" | 2653 | 570 | 420 | 472 | |

| 457 | 366 | 411 | 5" | 1-5/8" | 4" | 2653 | 570 | 420 | 497 | |

| 475 | 380 | 427 | 5" | 1-5/8" | 4" | 2653 | 570 | 420 | 522 | |

| 492 | 394 | 443 | 5" | 1-5/8" | 4" | 2653 | 570 | 420 | 547 | |

| 510 | 408 | 459 | 5" | 1-5/8" | 4" | 2653 | 590 | 480 | 524 | |

| 528 | 422 | 475 | 5" | 1-5/8" | 4" | 2653 | 590 | 480 | 544 | |

| 545 | 436 | 491 | 5" | 1-5/8" | 4" | 2653 | 590 | 480 | 565 | |

| 563 | 450 | 506 | 5" | 1-5/8" | 4" | 2653 | 590 | 480 | 585 | |

| 580 | 464 | 522 | 5" | 1-5/8" | 5" | 2653 | 590 | 480 | 605 | |

| 598 | 478 | 538 | 5" | 1-5/8" | 5" | 2653 | 590 | 480 | 629 | |

| 633 | 506 | 570 | 6" | 2-1/8" | 5" | 3310 | 590 | 480 | 665 | |

| 651 | 521 | 586 | 6" | 2-1/8" | 5" | 3310 | 590 | 480 | 675 | |

| 668 | 535 | 601 | 6" | 2-1/8" | 5" | 3310 | 590 | 480 | 685 | |

| 686 | 549 | 617 | 6" | 2-1/8" | 5" | 3310 | 590 | 480 | 695 | |

| 703 | 563 | 633 | 6" | 2-1/8" | 5" | 3310 | 670 | 530 | 714 | |

Notes:

- 1. Rated heat exchange parameters: evaporation temperature Te=2 ℃, inlet water temperature Ti=12 ℃, outlet water temperature To=7 ℃, overheat temperature 5 ℃.

- 2. Water source working condition parameters: evaporation temperature Te=3 ℃, inlet water temperature Ti=15 ℃, outlet water temperature To=8 ℃, overheat temperature 5 ℃. Heat exchange Q (water source) = 1.05Q (rated).

- 3. Refrigerant side max. allowable working pressure: 3.0 MPa, operating pressure: 2.5 MPa; water side max. allowable working pressure: 2.0 MPa.

- 4. Water pressure drop < 100 KPa.