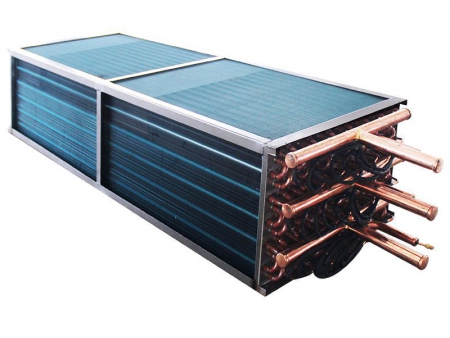

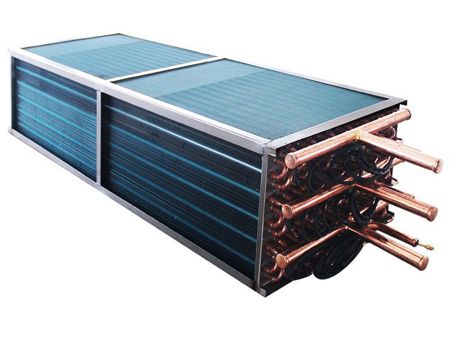

Finned Tube Heat Exchanger

Request a Quote

This finned tube heat exchanger tube employs a 9.52*0.3*0.17 thickened internal thread, with hydrophilic aluminum foil fin of 0.12mm thickness. The full set were manufactured automatically, including sheet metal, aluminum sheet, copper tube and bending, guaranteeing highest quality control. Utilizing the long U-pipe construction reduces the number of welds by 70%, thus reducing weld leakage.

Applications

The use of finned heat exchangers has drastically increased in engineering in recent times. Three key applications can be identified:

- Air-cooled condenser: This condenser is designed to be located outside, whilst the compressor and evaporator are inside of the building, which minimizes the risk of harm to the system's essential electrical parts and reduces the upkeep costs.

- Air-cooled evaporators utilized within dual-source heat pump systems are highly effective in reducing the average energy consumption.

- A dry cooler is an energy-efficient solution for cooler climates - often referred to as a 'winter energy saver'. It works by exchanging heat directly between high temperature water and lower air temperatures without the need for refrigerant. This drastically cuts down on the energy consumption of the system, due to the reduced work of fans and pumps.

Features

- The careful selection of energy efficient, low-noise fans, well-designed nozzles and fins arrangements will ensure efficient air flow and quiet operation.

- This finned tube heat exchanger features a fan of IP54 protection and F insulation class, resulting in a more reliable operation and extended service life.

- Explosion-proof fans, copper foil, anti-corrosion coatings, stainless steel heat exchanger tubes, and stainless steel sheet metal are available for selection to enhance usability and meet working conditions.

Specifications

Air-cooled Condenser, 2.2mm fin spacing

| Model | | | | | | | | |||

| Nominal heat exchange capacity | R404A | Δ | kW | 235.86 | 284.84 | 348.49 | 421 | 464.84 | 560.17 | 588.54 |

| Y | 180.44 | 206.01 | 266.46 | 306.19 | 354.61 | 405 | 444.83 | |||

| R22 | Δ | 231.1 | 275.42 | 343.81 | 407.52 | 451.27 | 540.8 | 559.19 | ||

| Y | 175.19 | 196.91 | 259.89 | 292.99 | 343.89 | 388.52 | 423.93 | |||

| Air flow | Δ | M³/h | 71234 | 65922 | 106807 | 98832 | 142410 | 131767 | 178077 | |

| Y | 45116 | 43250 | 67639 | 62219 | 90180 | 82933 | 112738 | |||

| Fan motor | Δ | Phase | 3 | 3 | 3 | 3 | 3 | 3 | 3 | |

| Y | ||||||||||

| Δ | W | 10400 | 10400 | 15600 | 15600 | 20800 | 20800 | 26000 | ||

| Y | 6400 | 6400 | 9600 | 9600 | 12800 | 12800 | 16000 | |||

| Δ | A | 19.02 | 19.02 | 28.80 | 28.80 | 38.40 | 38.40 | 48.00 | ||

| Y | 10.80 | 10.80 | 16.20 | 16.20 | 21.60 | 21.60 | 27.00 | |||

| Fan | NOXΦ | 2x2x630 | 2x2x630 | 2x3x630 | 2x3x630 | 2x4x630 | 2x4x630 | 2x5x630 | ||

| Noise level | Δ | DB(A)10m | 64 | 64 | 66 | 66 | 67 | 67 | 68 | |

| Y | 57 | 57 | 59 | 59 | 60 | 60 | 61 | |||

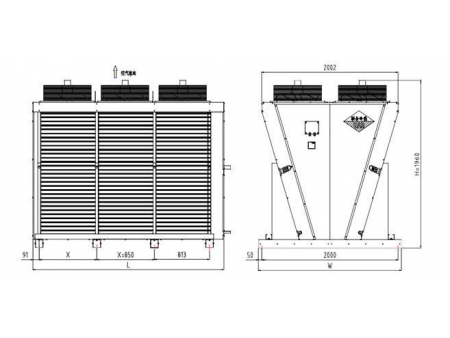

| Dimensions | L | mm | 1970 | 1970 | 2820 | 2820 | 3670 | 3670 | 4520 | |

| W | mm | 2100 | 2100 | 2100 | 2100 | 2100 | 2100 | 2100 | ||

| H | mm | 1960 | 1960 | 1960 | 1960 | 1960 | 1960 | 1960 | ||

| Weight | Kg | 533 | 641 | 765 | 873 | 1025 | 1133 | 1275 | ||

| Outlet diameter | mm | 53.9x2 | 53.9x2 | 63.5x2 | 63.5x2 | 63.5x2 | 76.2x2 | 76.2x2 | ||

| Inlet diameter | mm | 41.28x2 | 41.28x2 | 53.9x2 | 53.9x2 | 53.9x2 | 63.5x2 | 63.5x2 | ||

Notes:

- 1. Rated heat exchange parameters: evaporation temperature Te=40 ℃, inlet water temperature Ti=30 ℃, outlet water temperature To=35 ℃, overheat temperature 5 ℃.

- 2. Water source working condition parameters: evaporation temperature Te=35 ℃, inlet water temperature Ti=18 ℃, outlet water temperature To=29 ℃, overheat temperature 5 ℃. Heat exchange Q (water source) = 1.18Q (rated).

- 3. Refrigerant side max. allowable working pressure: 4.5 MPa, operating pressure: 3.8 MPa; water side max. allowable working pressure: 2.0 MPa.

- 4. Water pressure drop < 100 KPa.

Optional

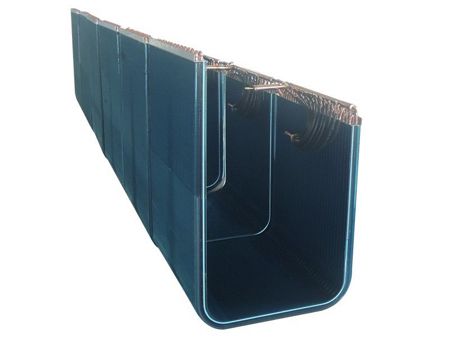

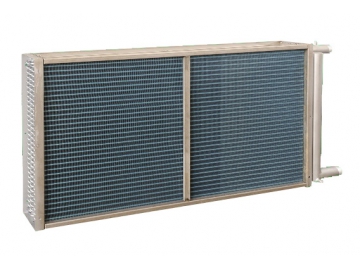

Heat exchanger tube

- Copper fin heat exchanger

Copper has become a top pick for heat exchangers due to its high heat transfer coefficient and ease of processing. Boasting a competitive price, copper is a popular choice in the heat exchanger industry and can be found in offshore drilling platforms, ships, and coastal air-cooled equipment. - Stainless steel fin heat exchanger

Stainless steel is a versatile material, with its beautiful aesthetic, corrosion-resistant properties, and wide range of applications. From fins, heat exchanger tubes, and sheet metal to other materials, stainless steel fin heat exchangers can be used in cooling organic gases, flue gases, and steam. Thus, it is a highly sought-after material for a variety of industries.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos