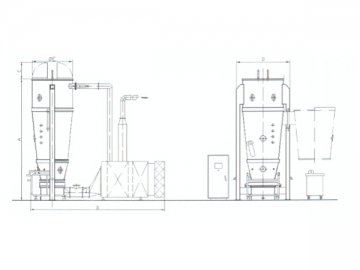

Fluidized Bed Granulator

Description:

It is recognized that fluidized bed granulator is an organic combination of mechanical design and preparation technology . Therefore hundreds of Granulating machines either for China or oversea countries like USA, Japan, Indonesia, Iran and many other countries are specially designed in accordance with the material characteristics and process requirements. So far, we have manufactured ten specifications, a total of 150 kinds of models to meet the different requirements, these practical experiences are very beneficial to old customers or new clients in the future..

Features:

By powder granulation process, the fluidity is improved and the dust leakage is reduced;

By powder granulation process, its solubility is improved,the prepared granules are instant , and granules are soluble, tablets are easy to disintegrate.

Mixing, granulation and drying processes are completed in one step inside the machine;

The operation is safe because the anti-static bag filter is applied.

It's safe for operator if explosion takes place, because an explosion proof type pressure-releasing vent is set;

No dead corners. Therefore the loading and unloading are quick, and it can be washed clean, so it meets the requirements of GMP.

The degree of automation is further improved, and the operation is simple, so the stability of product quality can be effectively guaranteed .

Applications:

Pharmaceutical industry :tablet capsule, instant soluble medicine, low sugar or no sugar granule of Chinese traditional medicine, capsule granule.

Foodstuff:cocoa, coffee, milk powder, juice of granulate, flavoring and so on.

Other industries: pesticide, feed-stuff, chemical fertilizer, pigment, dyestuff and so on.

Drying: wet powder or granule material;

Coating: pill protection layer, coloring, controlled release, thin film, or bowels solved coating of granules and pills.

Principle:

The powder granule in vessel (fluid bed) appears in a fluidized state. It is preheated and mixed with clean and heated air. At the same time the solution of adhesive agent is sprayed into the container. It makes some of the particles become granule that contains adhesive. Being of unceasing dry through hot air, the moisture in the granule is evaporated and the adhesive agent is solidified. The process is carried out continuously. Finally it forms ideal, uniform and porous granules.

| item | unit | spec | ||||||||||

| 3 | 5 | 15 | 30 | 60 | 120 | 200 | 300 | 500 | 1000 | |||

| vessel | volume | L | 12 | 22 | 45 | 100 | 220 | 420 | 670 | 1000 | 1500 | 3000 |

| diameter | mm | 300 | 400 | 550 | 700 | 1000 | 1200 | 1400 | 1600 | 1800 | 2200 | |

| capability | min | kg | 1.5 | 4 | 10 | 15 | 30 | 80 | 100 | 150 | 250 | 800 |

| max | kg | 4.5 | 6 | 20 | 45 | 90 | 160 | 300 | 450 | 750 | 1200 | |

| fan | velocity | m3/h | 1000 | 1200 | 1400 | 1800 | 3000 | 4500 | 6000 | 7000 | 8000 | 13670 |

| pressure | mmH2O | 375 | 375 | 480 | 480 | 950 | 950 | 950 | 950 | 950 | 1400 | |

| power | kw | 3 | 4 | 5.5 | 7.5 | 11 | 18.5 | 30 | 37 | 45 | 90 | |

| steam consumption | kg/h | 15 | 23 | 42 | 70 | 141 | 211 | 282 | 366 | 451 | 750 | |

| compressed air expenditure | m3/min | 0.9 | 0.9 | 0.9 | 0.9 | 1.0 | 1.0 | 1.1 | 1.5 | 3.0 | 4.0 | |

| weight of the main body | kg | 500 | 700 | 900 | 1000 | 1100 | 1300 | 1500 | 1800 | 2500 | 3500 | |

| steam pressure | MPA | 0.1-0.4 | ||||||||||

| temperature | ℃ | adjustable at the range from room temperature to 120℃ | ||||||||||

| working time | min | 45-90 decided in accordance with the properties of raw materials | ||||||||||

| collect rate | % | ≥99 | ||||||||||

| noise | dB(A) | ≤75dB(A) when do installation ,main machine is separated from fan. | ||||||||||

| size (L×W×H) | m | 1.0×0.6 ×2.1 | 1.2×0.7 ×2.3 | 1.25×0.9 ×2.5 | 1.6×1.1 ×2.5 | 1.85×1.4 ×3 | 2.2×1.65 ×3.3 | 2.34×1.7 ×3.8 | 2.8×2.0 ×4.5 | 3×2.25 ×5.0 | 4×2.8×7.2 | |