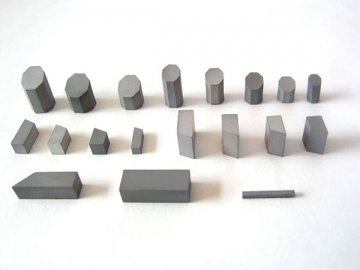

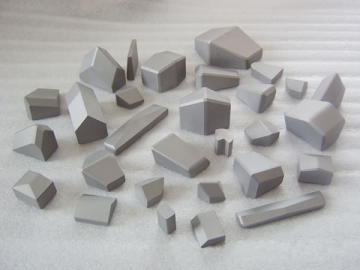

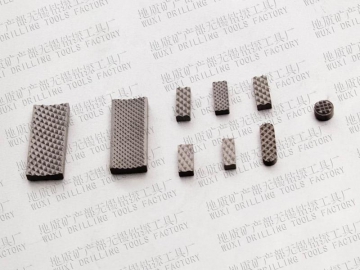

Carbide Tips (for Geological Exploration Tools)

Geological Exploration Tungsten Carbide Tools / Tungsten Carbide Tips for Geological Exploration

Features of the spherical tungsten carbide buttons are listed below. For more details and specific types, please contact us directly.

1. These tungsten carbide tips are made of special, high quality raw materials. They feature stable properties, and increase the yield in drilling and mining bits.

2. An extra grain size is available, which offers a higher impact resistance and lower hot cracks and breakage.

3. Each rod and tip is ground and tumbled, ensuring a uniform dimension and surface smoothness, making them easier to mount on geological exploration tools.

4. HIP sintered, which increases the strength of the carbide tips, thus extending the service life.

A full range of types and specifications are available, and our most popular grades and applications are listed below.

Applications

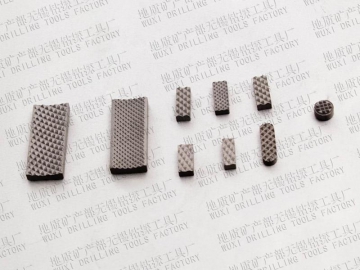

Tungsten carbide tips (also known as percussion bits and inserts for rotary prospecting bits) are used to cut soft, medium and hard formations.

These tungsten carbide products are also used as buttons in small and medium-sized percussion bits and inserts for rotary prospecting bits to cut soft, medium and hard formations.

They are also used as small buttons for percussion bits and inserts of rotary prospecting bits to cut soft, medium and hard formations.

Finally, they are also used as inserts and buttons for rotary percussive biaxial cutting bits and tricone bits to cut medium formations.

| Grades | Density(g/cm3) | Hardness(HRA) | TRS(N/mm2) | Application |

| YG3 | 15.1 | 91 | 1600 | finish and semi-finish continuous cutting of cast iron, nonferrous and non-metallic materials. |

| YG3X | 15 | 91.5 | 1500 | finish of cast iron and nonferrous materials |

| YG6 | 14.9 | 90 | 2000 | semi-finishing of cast iron and nonferrous materials |

| YG6X | 14.9 | 91 | 1900 | semi-finishing and finishing of chilled alloy cast iron and heat-resisting cast iron |

| YG6A | 14.85 | 91.5 | 1800 | semi-finishing and finishing of chilled cast iron, nonferrous metals, high-manganese steel, hardened steel and alloy steel. |

| YG8 | 14.7 | 89.5 | 2100 | roughing of cast iron, nonferrous metals and their alloys. |

| JN8 | 14.7 | 90.5 | 2500 | roughing semi-finishing of cast iron, nonferrous metals and their alloys. |

| YT15 | 11.25 | 91.5 | 1600 | semi-finishing turning of steel and cast steel. |

| YT14 | 11.4 | 91 | 1750 | semi-finishing turning of steel and cast steel. |