Hydraulic Ironworker

General Description of Hydraulic Ironworker

Q35Y series hydraulic ironworker machine is used for shearing, punching and die cutting of metal plate, square steel, round steel, angle steel, tool steel. It adopts the hydraulic transmission. We have five models of hydraulic ironworker with punching force from 35 Ton to 145 Ton.

Features of Hydraulic Ironworker

The excellent design and workmanship ensures this hydraulic ironworker to enjoy the following advantageous features

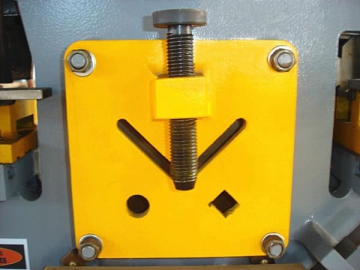

1.Punching position: There is a large-sized window on the stripper, a window that enjoys a rotary-open design, quite easy to operate. The two big measuring boards attached with rulers and stop supporting devices are standard facilities.

The quick-change coupling nut and connecting sleeve could return quickly.

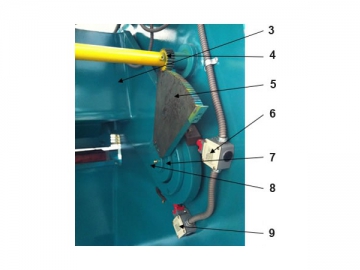

2. Slot position: the special design of this slot position could ensure precise shearing of square steels and steel bars. The electrical safety interlock guarantees the safe operation of this multi-function ironworker. The ventilation promotes the visibility for manipulators. At last, the three stop brackets for measurement could ensure the high precision of positioning.

3. Punching section: this section could provide unique structures for upper and lower dies of various specifications. Therefore, this hydraulic ironworker could punch large-sided square steels and channel irons.

4. Thanks to its unique design, this ironworker machinecould shear square steels from the steel’s upper and lower ends with a 45° angle.

5. Die-cutting section: this section enjoys a special design that makes the shearing device attached with a safety interlock, effectively protecting the operators during the process of square steels and flat steels. The ventilation device could ensure high visibility for operators. Moreover, three stop dogs are designed to ensure accurate positioning.

6. High precision shearing: with this versatile metal fabrication machine, various metal materials could be sheared with a 45° angle with minimum deformation and loss.

7. Shearing of flat steel: the binder foot of this machine tool is easy to adjust and could ensure the precision of shearing operation.

8. Shearing section for round steel and square steel: there are couples of punching holes available for users to choose according to the specific applications. The adjustable binder foot makes it easier to process all sizes of beams, I-beams and channel irons. Blades could be provided according to customers’ needs.

Specifications of Hydraulic Ironworker(35Y-12)| Model | |||

| Punching force(T) | 35 | ||

| Maximum thickness of plate(mm) | 12 | ||

| Sheet strength(N/mm) | ≤450 | ||

| Shear angle | 7° | ||

| Shearing area for a single stroke(thickness x width)(mm) | 12×1606×300 | ||

| Slide stroke | 35 | ||

| Number of stroke(times/min) | 10-18 | ||

| Throat depth(mm) | 115 | ||

| Thickness of punching hole(mm) | 12 | ||

| Max diameter of punching hole(mm) | 25 | ||

| Power of master motor(kW) | 4 | ||

| Dimension(length x width x height)mm | 950×550×1800 | ||

| Steel types | Round steel | square steel | Equal leg angles |

| 90° shear angle | |||

| Cross section |  |  |  |

| Q35Y-12 | 35 | 30×30 | 86×86×8 |

| Model | ||||||||

| Punching force(T) | 60 | |||||||

| Maximum thickness of plate(mm) | 16 | |||||||

| Sheet strength(N/mm) | ≤450 | |||||||

| Shear angle | 7° | |||||||

| Shearing area for a single stroke(thickness x width)(mm) | 16×250 8×400 | |||||||

| Slide stroke | 80 | |||||||

| Number of stroke(times/min) | 11-20 | |||||||

| Throat depth(mm) | 300 | |||||||

| Thickness of punching hole(mm) | 16 | |||||||

| Max diameter of punching hole(mm) | 25 | |||||||

| Power of master motor(kW) | 5.5 | |||||||

| Dimension(length x width x height)mm | 1700×750×1800 | |||||||

| Steel types | Round steel | Square steel | Equal leg angles | T-beam | I-beam | Channel iron | ||

| 90° shear angle | 45°shear angle | 90° shear angle | 45°shear angle | |||||

| Cross section |  |  |  |  |  |  | ||

| Q35Y-16 | 45 | 40×40 | 120×120×12 | 50×50×5 | 125×125×12 | 60×60×8 | 120×74×5 | 120×53×5.5 |

| Model | ||||||||

| Punching force(T) | 90 | |||||||

| Maximum thickness of plate(mm) | 20 | |||||||

| Sheet strength(N/mm) | ≤450 | |||||||

| Shear angle | 8° | |||||||

| Shearing area for a single stroke(thickness x width)(mm) | 20×330 10×480 | |||||||

| Slide stroke | 80 | |||||||

| Number of stroke(times/min) | 10-20 | |||||||

| Throat depth(mm) | 355 | |||||||

| Thickness of punching hole(mm) | 20 | |||||||

| Max diameter of punching hole(mm) | 30 | |||||||

| Power of master motor(kW) | 7.5 | |||||||

| Dimension(length x width x height)mm | 1950×900×1950 | |||||||

| Steel types | Round steel | Square steel | Equal leg angles | T-beam | I-beam | Channel iron | ||

| 90° shear angle | 45°shear angle | 90° shear angle | 45°shear angle | |||||

| Cross section |  |  |  |  |  |  | ||

| Q35Y-20 | 50 | 50×50 | 140×140×12 | 50×50×5 | 140×140×12 | 70×70×10 | 160×86×6 | 160×60×6.5 |

| Model | ||||||||

| Punching force(T) | 120 | |||||||

| Maximum thickness of plate(mm) | 25 | |||||||

| Sheet strength(N/mm) | ≤450 | |||||||

| Shear angle | 8° | |||||||

| Shearing area for a single stroke(thickness x width)(mm) | 25×330 16×600 | |||||||

| Slide stroke | 80 | |||||||

| Number of stroke(times/min) | 8-18 | |||||||

| Throat depth(mm) | 400 | |||||||

| Thickness of punching hole(mm) | 25 | |||||||

| Max diameter of punching hole(mm) | 35 | |||||||

| Power of master motor(kW) | 7.5 | |||||||

| Dimension(length x width x height)mm | 2355×960×2090 | |||||||

| Steel types | Round steel | Square steel | Equal leg angles | T-beam | I-beam | Channel iron | ||

| 90° shear angle | 45°shear angle | 90° shear angle | 45°shear angle | |||||

| Cross section |  |  |  |  |  |  | ||

| Q35Y-25 | 60 | 50×50 | 160×160×14 | 60×60×6 | 160×160×14 | 80×80×10 | 200×102×9 | 200×75×9 |

| Model | ||||||||

| Punching force(T) | 145 | |||||||

| Maximum thickness of plate(mm) | 30 | |||||||

| Sheet strength(N/mm) | ≤450 | |||||||

| Shear angle | 8° | |||||||

| Shearing area for a single stroke(thickness x width)(mm) | 30×335 20×600 | |||||||

| Slide stroke | 80 | |||||||

| Number of stroke(times/min) | 7-16 | |||||||

| Throat depth(mm) | 600 | |||||||

| Thickness of punching hole(mm) | 26 | |||||||

| Max diameter of punching hole(mm) | 38 | |||||||

| Power of master motor(kW) | 11 | |||||||

| Dimension(length x width x height)mm | 2680×1040×2300 | |||||||

| Steel types | Round steel | Square steel | Equal leg angles | T-beam | I-beam | Channel iron | ||

| 90° shear angle | 45°shear angle | 90°shear angle | 45°shear angle | |||||

| Cross section |  |  |  |  |  |  | ||

| Q35Y-30 | 65 | 55×55 | 180×180×16 | 80×80×10 | 180×180×16 | 80×80×10 | 280×124 ×10.5 | 280×86 ×11.5 |