Wheel Rim Production Line

XIAOYA offers design and customization services for full wheel rim production lines, including coiling, cutting, rim rolling, welding, trimming, installation, testing, and wheel production. We also customize wheel production tools for automatic wheel production. Different bespoke wheel production lines are available according to specific customer requirements.

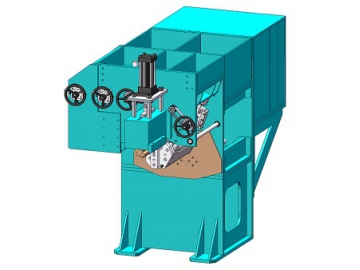

The wheel rim production line consists of:- Rim Preparation Line

- Rim Profiling Line

- Rim Testing Line

- Disc Forming Line

- Rim and Disc Assembly Line

Each production line is comprised of .

Main wheel rim production line typesAccording to wheel rim size and specifications, XIAOYA’s wheel rim production lines are classified into 3 categories: small rim line, large rim line, and extra-large rim line.

- Small rim production line: ideal for the production of passenger car wheel rims in an applicable diameter of 13 to 18 inches, a rim width of 3 to 10 inches, and a steel plate thickness of no more than 4mm.

- Large rim production line: provides tubeless wheel rims for trucks, buses and other large vehicles. Applicable diameter: 17.5-26 inches; rim width: 5.5-16inches; steel plate thickness: no more than 8mm.

- Extra large rim production line: specially designed to produce wheel rims for engineering vehicles, farm vehicles, tractors and other wheeled equipment. Applicable diameter: 20-54 inches, rim width: 7-28inches, steel plate thickness: no more than 8mm.

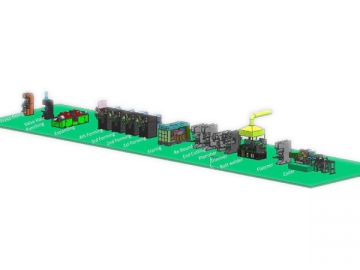

The wheel rim production line primarily involves the following processes:

Rim band feeding

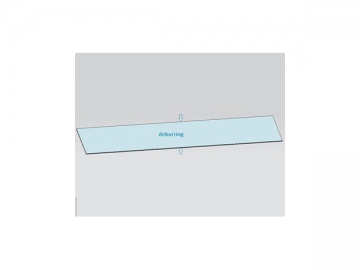

Rim band feeding Deburring for both side

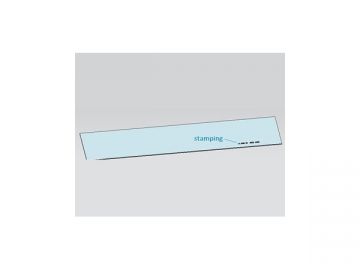

Deburring for both side  Stamp mark

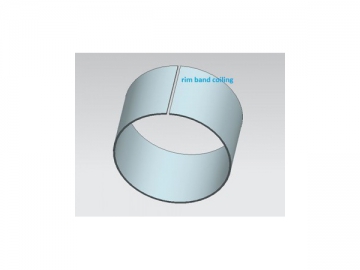

Stamp mark  Rim band coiling

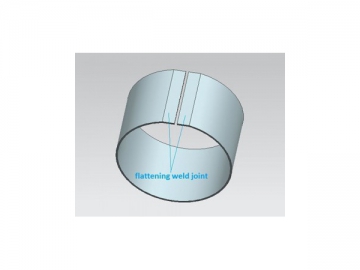

Rim band coiling  Flattening weld joint

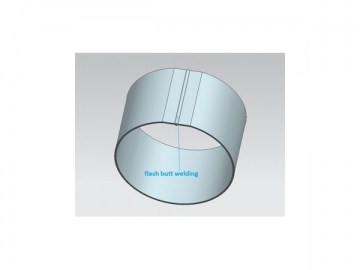

Flattening weld joint  AC flash butt welding

AC flash butt welding  Trimming welding slag

Trimming welding slag  Planishing welding seam

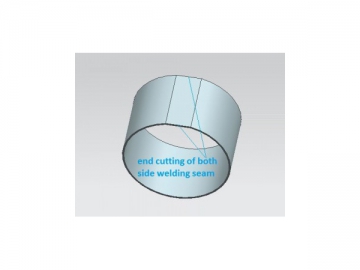

Planishing welding seam End cutting of welding’s lag

End cutting of welding’s lag  Cooling

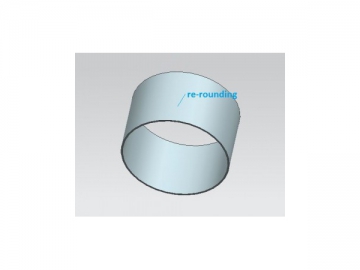

Cooling  Re-rounding

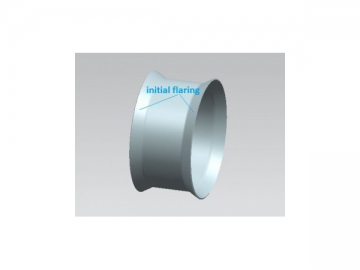

Re-rounding  Initial flaring

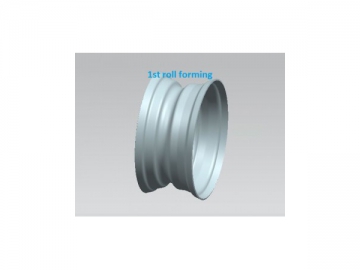

Initial flaring  1st roll forming

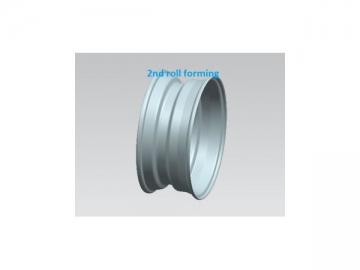

1st roll forming  2nd roll forming

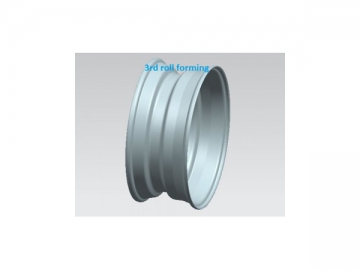

2nd roll forming  3rd roll forming

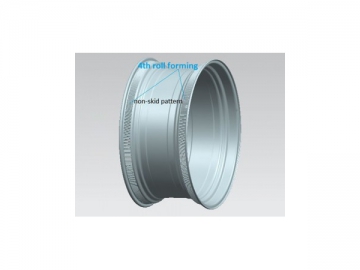

3rd roll forming  4th roll forming for non-skid pattern

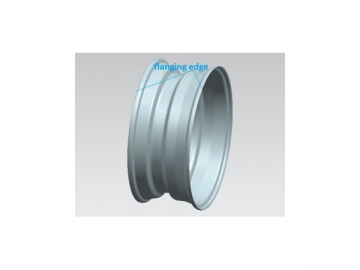

4th roll forming for non-skid pattern  Flanging edge

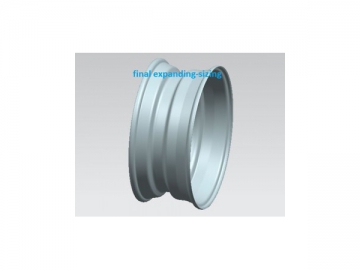

Flanging edge  Final expanding-sizing

Final expanding-sizing - Valve hole punching

- Press disc into rim

- Combined welding for rim and disc

- Automatic feeding and unloading

The outfeed conveyor operates throughout the full wheel rim production line to connect each step. Hands free feeding and discharging saves labor and enhances the efficiency.

- Digitization distributed control system for wheel rim production line

The digitization distributed control system controls any complex processing tasks. This control system features one computer to control all workshop appliances and uses the computer to check real-time working status for each equipment piece. This wheel rim production line features a multi-stage alarm function, ensuring the computer displays the alarm in each stage accurately and in real time. This ensures operators are aware of when equipment fails or requires maintenance and gives operators access to information regarding equipment daily output.

- Automatic testing technology

XIAOYA’s automatic steel wheel production line features a complete inspection including leak testing and run-out measuring, unlike spot checking found in traditional wheel production lines. This not only tests product quality, but also collects real time data for system processing processes. This allows for a full process monitor and tracking of product parameters and technological processes, then effectively ensures product quality to improve the product pass rate. Detailed information regarding the wheel rims can be found at any time in the database, and real time monitoring of any quality problems occurs in each production step.

- Innovative processing techniques reduce energy consumption and maximizes economic raw material usage.

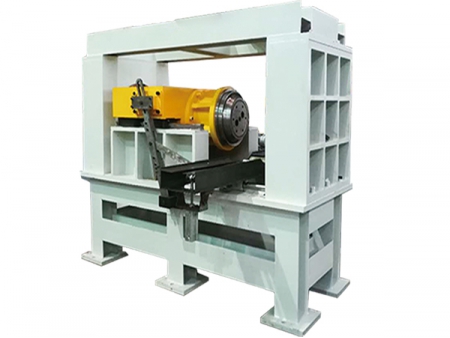

The wheel rim production line features a more streamlined process compared to other wheel rim production lines. For example, a traditional valve hole punch press has only one station and needs to work with a deburring machine. However, XIAOYA’s valve hole punch press features a 6-station rotary automatic punching process that integrates feeding, planishing, punching, deburring, and discharging, turning it into a piece of highly automated equipment. The welding head on the butt welding machine rotates up to 360 degrees or carries out skip welding, as well as automatically lowers or heightens the welding height.

- Computer industry image recognition system to identify wheel rims

XIAOYA independently developed a steel wheel production line that is equipped with a computer industry image recognition system to automatically identify different wheel rim types. Controlled and managed via computer, it allows the machine to adjust the process for other part types according to computer instructions after processing a different part, with no need to shut the equipment down for adjustment.

- A combination of a computer hydraulic system, velocity compensation and other advanced technologies improves the positioning accuracy, ensures product quality and enhances productivity.

XIAOYA’s independently developed automatic wheel rim production line has improved upon traditional equipment, and applies the use of a hydraulic system, velocity compensation and other advanced technologies. For example, an auxiliary roll is added to the feeding end of the outfeed conveyor to position and allow plate materials to automatically straighten when they are being fed, in order to position the plates precisely along the width direction.