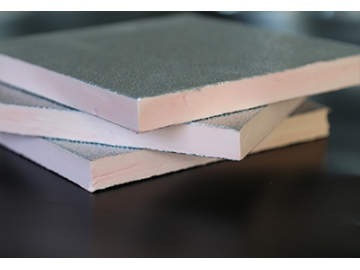

Aluminum Sheet Composite Insulation Board

Application

The aluminum sheet composite insulation board is widely used in central air conditioning ventilation systems in both public and civil sectors, as well as industrial factory buildings. It is popular with engineering design units, development organizations and terminal users.

Characteristics

The aluminum sheet composite insulation board is produced using our unique process formula, and features an excellent flame retardant and fireproof performance, excellent absorption performance, as well as a number of advantages, including an anti-bacterial structure that makes it healthy for use, a light weight, long service life and easy to install design.

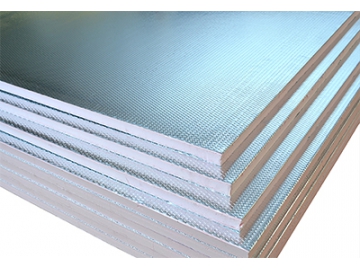

| Thickness (mm) | 20, 25, 30 |

| Dimension (mm) | 2000*1200,3000*1200,4000*1200 |

| Fire-Protection Rating | Nonflammable B1 level |

| Density(kg/m³) | 60~70 |

| Water Absorption | ≤3.7% |

| Thermal Conductivity W/(m•K) | 0.024-0.034 |

| Temperature Range(℃) | -150~150 |

| Wind Resistance Strength (Pa) | ≤2000 |

| Compressive Strength(MPa) | ≥0.18 |

| Bending Strength(MPa) | ≥1.1 |

| Leakage Air Volume | ≤1.2% |

| Thermal Resistance(㎡K/W) | 0.86 |

| Smoke Density | ≤9, no release of toxic gases |

| Dimensional Stability | ≤2%(70±2℃, 48h) |

| Oxygen Index | ≥45 |

| Fire Endurance | >1.5h |

| Formaldehyde Emission | ≤0.5mg/L |

| Air Flow Max | 15M/S |

Remarks: We can also customize various sizes according to the customer's requirements.

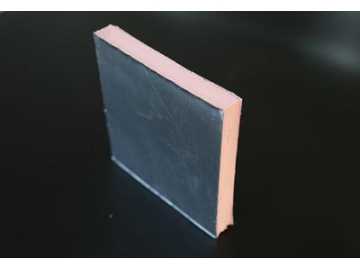

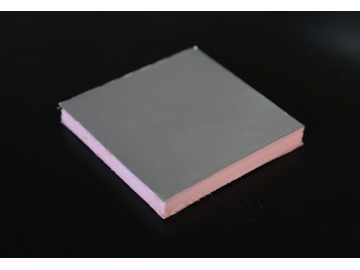

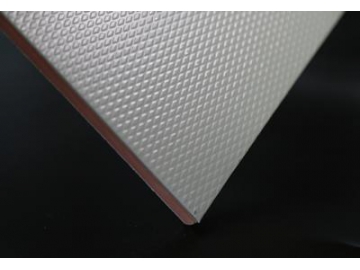

The aluminum sheet composite insulation board a high tech composite insulation material that was independently researched and developed by us. It is a product that has been improved upon a basis of an aluminum foil faced insulation board and a new nano anti-bacterial coating to effectively prevent the breeding of bacteria in the air duct, prevent the formation of mildew in dark and humid environments on the inner wall, and avoid air pollution in the air duct so as to ensure the best possible indoor air quality. Under the same production process of the aluminum foil faced insulation board, we have replaced the outer aluminum foil with a nano-antibacterial coating aluminum plate, or replaced the double sided aluminum foil with the nano-antibacterial coating aluminum plate, which significantly enhances the strength of the insulation board, as well as improves durability and anti-bacterial performance. For an added appearance, we can emboss the surface based on customer requirements. Currently, we have two productions of the series: a one sided aluminum sheet composite insulation board and a two sided aluminum composite insulation board.

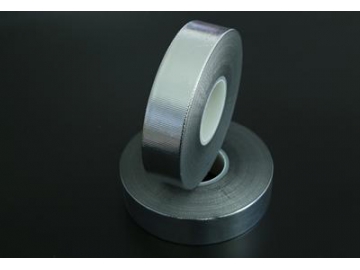

WT Thermal Insulation Material is manufacturing and offering aluminized fabrics and fiberglass coated products and some others feature aluminum foils or silicone laminating, these products extend to aluminum foil wrap, aluminum foil laminated fabrics, and adhesive aluminum tapes, aluminum foil fabrics covered insulation foam board etc. We can offer different products that are made with aluminum foils by coating, laminating, or covering; rich experiences and enough knowledge of manufacturing aluminum foil based products is our confidence to provide quality products to global markets.

Index

flame retardant board, composite board, thermal insulation board, foam board