Magnetic Disk Separation and Purification System

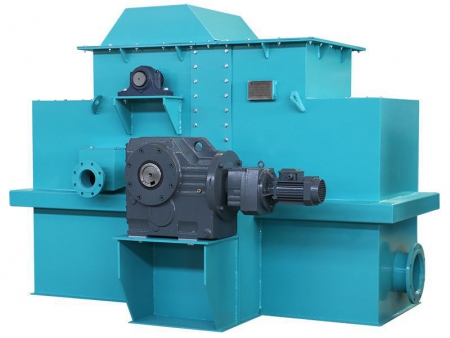

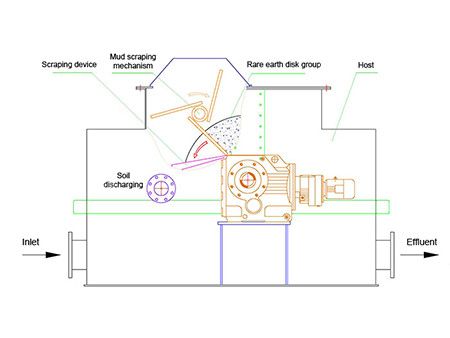

The advanced magnetic separator utilizes the potent magnetic energy derived from the neodymium-iron-boron, a rare-earth permanent magnet. This design innovation employs a magnetic assembly of the rare-earth disk, creating a high-intensity magnetic field with a steep gradient in the working area. This design ensures that the ferromagnetic particles present in sewage, wastewater, or water feed, along with non-magnetic particle flocs, can overcome fluid resistance, gravitational pull, and other mechanical forces due to the magnetic field. These particles exhibit rapid directional motion towards the rare-earth magnetic disk and get attached to its surface, thereby facilitating the separation of suspended matter from wastewater. Subsequently, a magnetic separation device removes these adsorbed materials from the disk surface. They are then transferred into a sewage discharge channel and extracted via a pressure water or slag conveying system. This process enables effective purification and recycling of wastewater.

| Model | Max. flow rate (m³/h) | Dimensions | Weight | Main power (kW) | Scraper power (kW) | Feeding power (kW) | Disc diameter (m) | Number of disc |

| | 60 | 2500×1960×1750 | 1800 | 0.55 | 0.75 | 0.75 | 1.0 | 9pcs |

| 80 | 2500×2050×1750 | 2000 | 0.55 | 0.75 | 0.75 | 1.0 | 11pcs | |

| 120 | 2500×2230×1750 | 2200 | 0.55 | 0.75 | 0.75 | 1.0 | 16pcs | |

| 150 | 2500×2650×1750 | 2500 | 0.55 | 0.75 | 0.75 | 1.0 | 20pcs | |

| | 60 | 2500×1960×1750 | 1800 | 0.55 | 0.75 | 0.75 | 1.0 | 9 pcs |

| | 80 | 2500×2050×1750 | 2000 | 0.55 | 0.75 | 0.75 | 1.0 | 11 pcs |

| | 120 | 2500×2230×1750 | 2200 | 0.55 | 0.75 | 0.75 | 1.0 | 16 pcs |

| | 150 | 2500×2650×1750 | 2500 | 0.55 | 0.75 | 0.75 | 1.0 | 20 pcs |

| | 200 | 3300×3160×2400 | 5900 | 0.75 | 1.1 | 1.1 | 1.5 | 16 pcs |

| | 200 | 3300×3550×2400 | 6650 | 0.75 | 1.1 | 1.1 | 1.5 | 20 pcs |

| | 300 | 3300×3550×2400 | 7400 | 0.75 | 1.1 | 1.1 | 1.5 | 24 pcs |

| | 400 | 3400×3950×2400 | 9100 | 0.75 | 1.1 | 1.1 | 1.5 | 32 pcs |

| | 500 | 3400×4340×2400 | 11000 | 0.75 | 1.1 | 1.1 | 1.5 | 40 pcs |

| | 600 | 3400×4730×2400 | 12100 | 0.75 | 1.1 | 1.1 | 1.5 | 48 pcs |

| | 700 | 3450×5130×2400 | 13550 | 0.75 | 1.1 | 1.1 | 1.5 | 56 pcs |

| | 800 | 3450×5520×2400 | 15200 | 0.75 | 1.1 | 1.1 | 1.5 | 64 pcs |

For other technical parameters, please consult us. Xuyang has the right to modify the model and parameters without further notice.

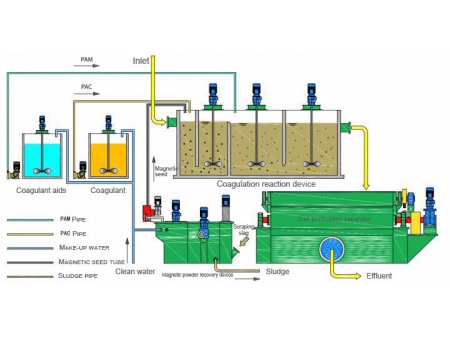

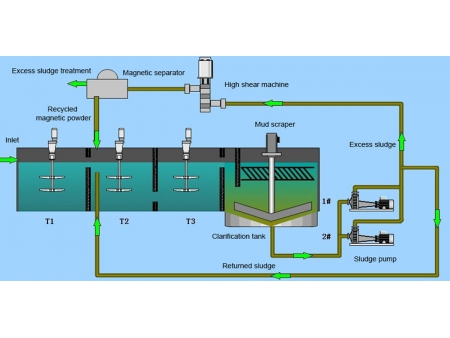

Brief description of process flow- A sewage pump extracts water from the inlet, transporting it to a coagulation reaction tank. Here, the water is uniformly mixed with a magnetic substance of a specific concentration.

- Once combined with the magnetic substance, the water undergoes a reaction facilitated by a coagulant and a coagulant aid. This reaction causes the magnetic and non-magnetic suspended substances to unite, resulting in the formation of magnetic flocs.

- After the coagulation, the water containing the magnetic flocs flows into a super magnetic separation device. Here, a magnetic disk isolates and purifies the magnetic flocs from the rest of the water. This process enables the purification and separation of the magnetic flocs from the water, which can then be discharged or reused.

- The separated micro-magnetic flocs are further processed by a magnetic powder recovery device. This separates them from the non-magnetic sludge, enabling the magnetic substances to be recovered for reuse. The remaining sludge is moved into a concentration tank, where it undergoes treatment by a sludge dehydrator.