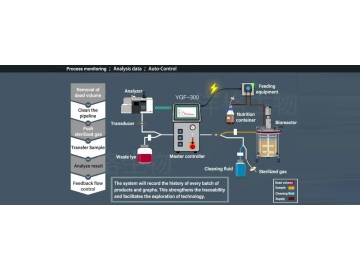

Automated On-line Sampling System

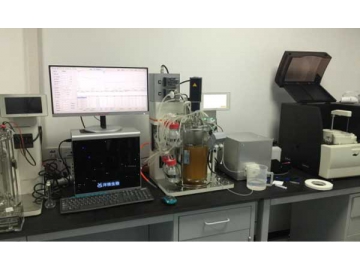

In the processes of cell cultivation and microbial fermentation, control of critical process parameters plays a vital role in ensuring successful experiment or production. Unlike conventional cultivation equipment that usually can only measure and control several common process parameters such as pH, DO, temperature, speed, etc., Jing Liang JL-YGZ600 automated on-line sampling system is capable of real-time controlling metabolites and calculating nutrient consumption in cell cultivation and microbial fermentation process, allowing user to precisely get information about the status of cell culture while achieving traceability.

You can contact us for a quotation or with any questions you may have on this product.

The automated on-line sampling system is mainly composed of three parts:

Automatic on-line sampling

Automatic biochemical analysis

Intelligent feedback control of fed-batch

| Item | Range (not prediluted) | Range (prediluted) |

| Glucose | 0.05~6g/L | 0.05~60g/L |

| Lactic acid | 0.05~5g/L | 0.05~50g/L |

| Glutamate | 15~1460mg/L | 15~14600mg/L |

| Glutamine | 15~1460mg/L | 15~14600mg/L |

| Glycerin | 0.05~2g/L | 0.05~20g/L |

| Methanol | 0.02~0.5g/L | 0.01~10g/L |

| Ethanol (alcohol content) | 0.02~1g/L | 0.04~20g/L |

| Lysine | 0.0~1.5g/L | 0.0~15g/L |

| Xylose | 0.05~2g/L | 0.05~20g/L |

| Galactose | 0.1~2g/L | 0.1~20g/L |

| pH | 6.0~8 | |

| Ammonium ion | 0.01~0.6g/L | 0.01~6g/L |

| Sodium ion | 20.0~200mmol/L | |

| Potassium ion | 0.5~15mmol/L | |

| Calcium ion | 0.1~5mmol/L |

-

- Fermentation Process Research and Development Project of Zhejiang SDSW Research Institute

- Project: Vitamin B2

- Reaction: 96 hours

- Item: glucose, lactic acid

- Testing time: 10min

- Object: 5L bioreactor

- Result: workers’ day and night shifts are cancelled during the cell culture process, feeding accuracy and product expression rate are improved by high-frequency sampling testing and feedback controlling of fed-batch.

-

- Cervical Cancer Vaccine Project of Jiangsu RKSW Pharmaceutical Technology Co., Ltd.

- Project: vaccine for cervical cancer

- Reaction: 80 hours

- Item: glycerin

- Testing time: 20min

- Object: three 30L bioreactors

- Result: workers’ day and night shifts are cancelled during the cell culture process, feeding accuracy and product expression rate are improved by high-frequency sampling testing and feedback controlling of fed-batch.

-

- YGF300 biochemistry analyzerPerformance Parameters:

- Sampling frequency and sampling rate can be set according to actual needs

- Fully automatic aseptic operation in sampling process

- Sampling rate: 2-10 ml/min

- Sampling interval: Min. 5min

- Sample volume: 0.5-5 ml

50W Automated Assembly Line Fiber Laser Marking Machine, MF50-B-A Laser Marking System

lasercut-group.com

50W Automated Assembly Line Fiber Laser Marking Machine, MF50-B-A Laser Marking System

lasercut-group.com

30W Automated Assembly Line Fiber Laser Marking Machine, MF30-B-A Laser Marking System

lasercut-group.com

30W Automated Assembly Line Fiber Laser Marking Machine, MF30-B-A Laser Marking System

lasercut-group.com