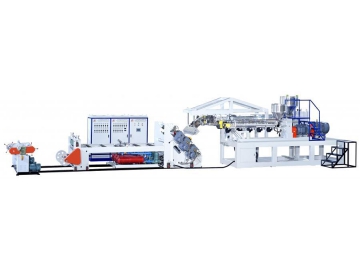

3-layer PE Film Co-Extrusion Blowing Machine

LANGYI's 3-layer film coextrusion blowing machine is designed to meet the customer's evolving demands. All models are equipped with high-performing extruders for minimized power consumption. The blown film is effectively cooled from the inside using internal bubble cooling, or IBC for short. Other desirable features in this multilayer blown film line include the 360 degree oscillating haul-off, deviation control system, automatic windup roller, idler rolls for tension adjustment, and computer display.

The high level of flexibility in the process allows the extruder to produce many different widths including 800mm and 1500mm, as well as various thicknesses ranging from 0.01mm to 0.1mm. Additionally, a wide selection of raw plastics can be used to produce blown films, such as the LDPE, HDPE, LLDPE, and MLLDPE. Compared with similar equipment, the 3-layer film coextrusion blowing machine has many benefits including higher productivity, better plasticization, lower energy consumption, and easier operation. The line is completed with automatic winder that provides exceptionally flat roll production. The resultant film is an ideal barrier against moisture, rain, wind, frost, oxygen, and oil. It is therefore widely used in packaging fruit, meat, vegetable pickles, fresh milk, and liquid drinks.

Features

1. The multi-layer spiral mandrel is able to rotate through 360 degrees.

2. Unique screen changer design allows fast replacement of filtering screens, thus making extrusion more reliable.

3. Other downstream components in this film coextrusion blowing machine include the length measuring device, slitter, cooling water drainage, nip rolls, and scrap material winder.

| Model No. | |||

| Screw Diameter | ф 50mm | ф 55mm | ф 65mm |

| L/D | 28:01:00 | 28:01:00 | 28:01:00 |

| Screw Rotation Speed | 15-150r/min | 15-150r/min | 15-150r/min |

| Main Motor Power | 11Kw×3 | 15Kw×3 | 18.5Kw×3 |

| Production Capacity per Extruder | 50kg/h | 80kg/h | 100kg/h |

| Die Exit Diameter | ф 120 φ 180 | ф 120 φ 250 | ф 120 ф 300 |

| Film Thickness per Layer | 0.01-0.10mm | 0.01-0.10mm | 0.01-0.10mm |

| Finished Film Roll Diameter | 1000mm | 1200mm | 1500mm |

| Installed Power | 76Kw | 88Kw | 102Kw |

| Dimensions | 6600 ×4100 ×5000mm | 6800 ×4300 ×6000mm | 7000 ×4800 ×6800mm |

| Weight | 4T | 5T | 6T |