EM12/EM12K Submerged Arc Welding Wire

The EM12/EM12K submerged arc welding wire is a copper coated filler wire. This welding consumable is characterized by superior weldability, stable arc, flawless bead appearance and easy slag removal. Our product is widely applied to welding of carbon steel (e.g. Q195, Q215 and Q235, etc.) and low-strength alloy steel such as 16MnCu and 16Mn, etc.

Our model of submerged arc welding wire is capable of catering to most welding conditions and requirement, including multi-layer and multi-pass welding in large current, as well as double-sided single-pass welding and high-speed welding, etc. This metal welding wire has been extensively applied to boilers, pressure vessels, bridges and ships, etc.

Standard

AWS EM12K

GB /T:H08MnA

DIN:S2 BS:S2

Available diameter

2.0mm, 2.5mm, 3.2mm, 4.0mm, 5.0mm

Applicable flux

Fused fluxes: HJ230, HJ330, HJ433 and HJ434, etc.

Agglomerated flux: SJ101, SJ107, SJ201, SJ301, SJ302, SJ501 and SJ503, etc.

| C | Mn | Si | P | S | Cr | Ni | Cu | |

| Typical | 0.08 | 0.91 | 0.04 | 0.018 | 0.012 | 0.02 | 0.01 | 0.15 |

| Standard | ≤0.10 | 0.80-1.10 | ≤0.07 | ≤0.030 | ≤0.030 | ≤0.2 | ≤0.30 | ≤0.20 |

Note: Cu content in copper coated submerged arc welding wire should not be more than 0.35%.

Mechanical properties of deposited metal (HJ230 Q215)| Rm (MPa) | Rel (MPa) | A (%) | Akv (J) (-20℃) | |

| Typical | 501 | 388 | 29 | 68 |

| Standard | 410-550 | ≥330 | ≥22 | ≥27 |

| Wire diameter(mm) | Current (A) | Voltage (V) | Current type | Wire feed speed (m/h) | Interpasstemperature (℃) | Stick-out (mm) | |

| 1.6 | 350 | 30 ±2 | DC/AC | 18 | ±1.5 | 135-165 | 13-19 |

| 2.0 | 400 | 30 ±2 | DC/AC | 20 | ±1.5 | 135-165 | 13-19 |

| 2.5 | 450 | 30 ±2 | DC/AC | 21 | ±1.5 | 135-165 | 22-35 |

| 3.2 | 500 | 30 ±2 | DC/AC | 23 | ±1.5 | 135-165 | 22-35 |

| 4.0 | 550 | 30 ±2 | DC/AC | 25 | ±1.5 | 135-165 | 25-38 |

| 5.0 | 600 | 30 ±2 | DC/AC | 26 | ±1.5 | 135-165 | 25-38 |

| 6.0 | 650 | 30 ±2 | DC/AC | 27 | ±1.5 | 135-165 | 25-38 |

Note: If values of welding current or voltage exceed recommended range above, negative impacts will be led to mechanical properties and wedability of submerged arc welding wire.

Recommended welding data for low alloy steel (DC )| Wire diameter(mm) | Current (A) | Voltage (V) | Current type | Wire feed speed (m/h) | Stick-out (mm) | Interpasstemperature (℃) | |

| 1.6 | 250-350 | 26-29 | DC/AC | 18 | ±1.5 | 13-19 | 150 ±15 |

| 2.0 | 300-400 | 26-29 | DC/AC | 18 | ±1.5 | 13-19 | 150 ±15 |

| 2.5 | 350-450 | 27-30 | DC/AC | 20 | ±1.5 | 19-32 | 150 ±15 |

| 3.0 | 400-500 | 27-30 | DC/AC | 23 | ±1.5 | 25-38 | 150 ±15 |

| 3.2 | 425-525 | 27-30 | DC/AC | 23 | ±1.5 | 25-38 | 150 ±15 |

| 4.0 | 475-575 | 27-30 | DC/AC | 25 | ±1.5 | 25-38 | 150 ±15 |

| 5.0 | 550-650 | 27-30 | DC/AC | 25 | ±1.5 | 25-38 | 150 ±15 |

| 6.0 | 625-725 | 28-31 | DC/AC | 29 | ±1.5 | 32-44 | 150 ±15 |

| 6.4 | 700-800 | 28-32 | DC/AC | 31 | ±1.5 | 38-50 | 150 ±15 |

Note: If values of welding current or voltage exceed recommended range above, negative impacts will be led to mechanical properties and wedability of submerged arc welding wire.

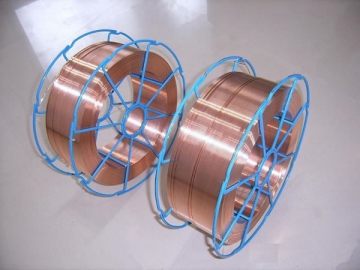

Packaging

1. 20kg plastic spool (Only for wire in Φ2.0mm)

2. 25kg/50kg/150kg/250kg/350kg transverse wind without core

3. 30kg/50kg bundle

4. 250kg drum