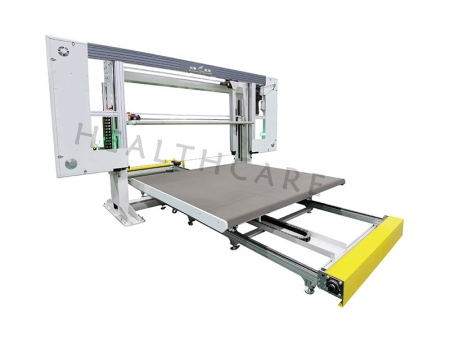

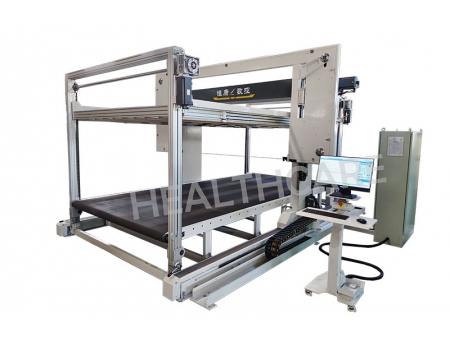

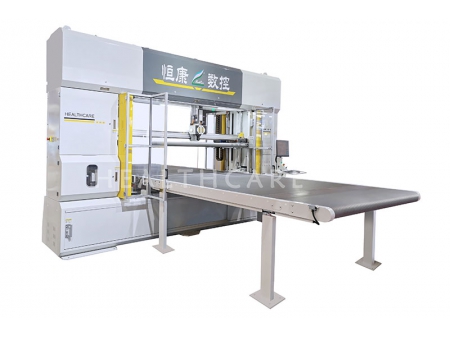

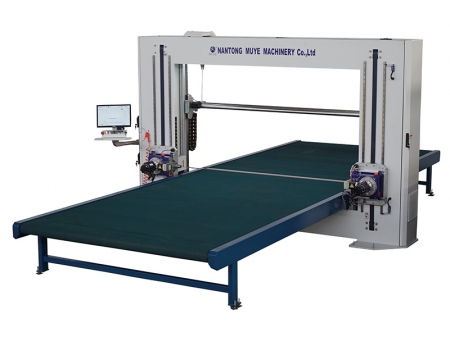

Horizontal Continuous Blade Contour Cutting Machine, CNCHK-9.2

CNC Foam Cutting Machine with Automatic Turntable

The advantage of the horizontal continuous blade contour cutting machine is its cutting speed, which is 3-5 times that of horizontal oscillating blade for contour cutting foam materials with ordinary hardness. This CNC foam cutting machine is designed with automatic foam size measuring device, roll compression unit with induction, automatic turntable, etc., which is suitable for foam fabrication in high volume. It can be upgraded to an automatic cutting line upon request.

The advantage of the horizontal continuous blade contour cutting machine is its cutting speed, which is 3-5 times that of horizontal oscillating blade for contour cutting foam materials with ordinary hardness. This CNC foam cutting machine is designed with automatic foam size measuring device, roll compression unit with induction, automatic turntable, etc., which is suitable for foam fabrication in high volume. It can be upgraded to an automatic cutting line upon request.

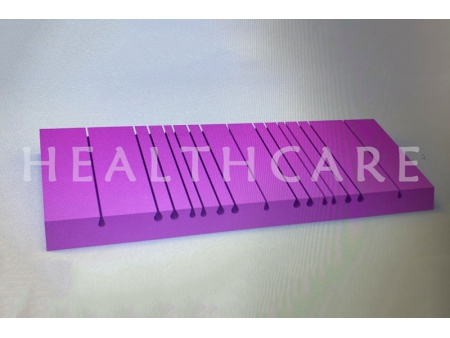

Memory foam pillow

Memory foam pillow Contour cut foam

Contour cut foam Acoustic foam

Acoustic foam

- Foam fabrication

- Upholstered furniture

- Mattress

- Packaging

- Automotive

- Household

- PU foam

- Memory foam

- Rebond foam

- Polyester fiber

| Working table size | 2500*2500mm |

| Cutting height | 1300mm |

| Toothed blade size | 12470*3.5*0.6mm |

| Torsion range of blade | ±360° |

| Turntable | Automatic |

| Cutting speed | 0-40m/min |

| Accuracy | ±1mm |

| Central blade support | Semi-automatic |

| Holding device | Press roller |

- High level of automation: foam size measuring, worktable rotation, operation of press roller

- High cutting speed and precision

- Few wear parts

- Simple operation with state-of-the art control technology

- Dust-free cutting: Foam is cleanly sliced, not abrasively cut, so there is no dust generated. A clean dust-free surface to the finished product is essential for mattresses, pillows and medical applications. This also helps keep a clean, safe workplace.

- The foam processing which is interrupted due to power outage will start from the breaking point after power on.

- Absolute value of system, stable and reliable.

- Automatic roll compression unit (press roller)

- Foam measuring system

- Automatic feeding and cutting system

- Automatic turntable

- Knife support device

- Worktable with extended length

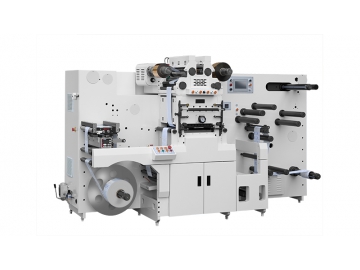

- Nesting software