Orbital Automatic Pipeline Welding Machine (FCAW/GMAW)

Request a Quote

Model: PAAWM-56Aa

Technical Parameters- Applicable Pipe Diameter: DN400-1400

- Applicable Wall Thickness: 6-80MM

- Applicable Materials: Carbon steel, alloy steel, stainless steel and low temperature steel (cryogenic steel), etc.

- Applicable Welding Seams: Have a big space that makes it easy to install the orbital track of the pipe welding.

- Power of Welding Head: 120W

- Travel Speed: 0-36m/h

- Oscillation Range: 2.5-30mm

- Oscillation Speed: 0-42mm/S

- Maximum Offset: 70mm

- Dwell Time: 0-2s

- Welding Waveform: Triangular waveform, trapezoidal waveform, rectangular waveform, and straight line

- Weight of Weld Head: 12kg

- Height of Welding Gun: 0-80 mm

- Angle of Welding Gun: 0-360°

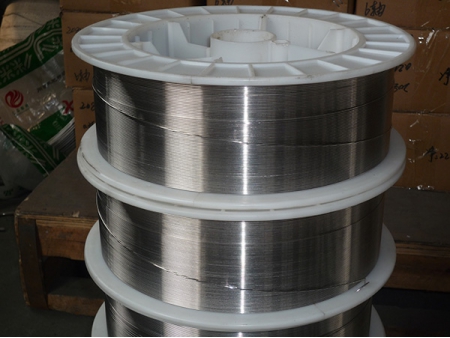

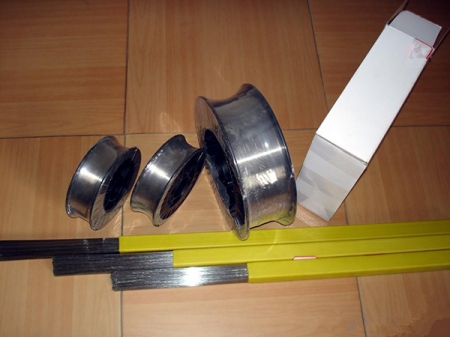

- Loading Welding Wire: 5kg

Applications

The orbital automatic pipeline welding machine is best used for welding big (middle) diameter and thick wall thickness fabricated welds which have long distance pipeline diameter for hot welding, filling and cap welding of circular welding.

- Automation level: Better (input all of the welding parameters before welding, and it can also control the machine real time when it is working)

- Beveling is required: After using STT semiautomatic welding to root welding, you can use this machine to weld.

- The orbital automatic pipeline welding machine has a better welding production capacity of 250-350 inch per day.

- The operability is Excellent / Better.

- The orbital automatic pipeline welding machine offers better surface shaping (welding gun always go along with the orbital track to welding of all position)

- It has a welding qualification ratio of over 96%.

- The orbital automatic pipeline welding machine's driving reliability is excellent. (Carriage forced going along with the orbital track.)

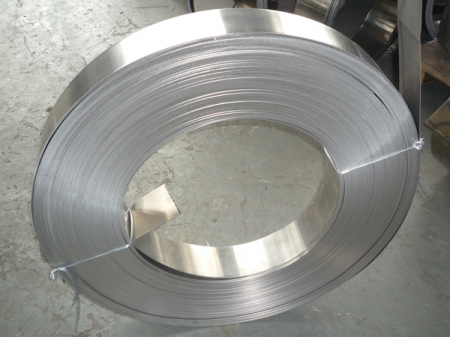

- Suitable for filling and cap welding in pipeline or on installation site; split type orbital track is installed outside the pipe; fast manual centering with screws; welding head is installed on the track. imported genuine MIG welding power supply which can tolerate the voltage fluctuation of generators; solid welding wire with mixed gas; downhill welding.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos