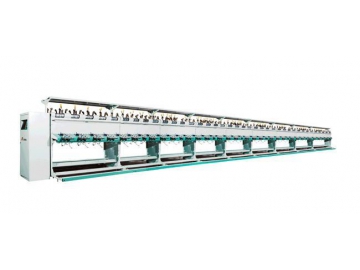

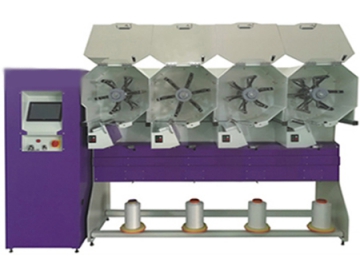

GH018-L High Speed Fully Drawn Yarn Thread Winding Machine

GH018-L High Speed Fully Drawn Yarn Thread Winding Machine

- Cones

for a conical package shape

- Tubes

for cops that are the most flexible base for a wide range of package shapes (e.g.: cylindrical - no taper / biconical - double taper / single taper / bottle shape), depending on the winding unit (type of winding)

- STSewing yarn

Sewing yarns are especially made to pass rapidly through a sewing machine. They are a fine cord of a fibrous material, which are made of two or more filaments twisted together. The yarns form efficient stitches without breaking or becoming distorted.

- Spun yarnStaple spun yarn

Textile yarn spun twisted from staple length fiber, either natural or synthetic.

- COCotton

Natural fibre from the cotton plant which is spun into fine yarn.

- CVViscose

Viscose, formerly known as viscose rayon, is made by treating cellulose with caustic alkali solution and carbon disulphide. It is a soft fibre commonly used in dresses, linings, shirts, shorts, coats, jackets, and other outerwear.

- TYTechnical Yarns

The yarns are used for technical textile products, which are manufactured for non-aesthetic purposes. The function such as rigidity, strength, dimension stability, design flexibility and economic viability is main feature.

GH018-L high speed fully drawn yarn thread winding machine is mainly used to wind yarns from hank to cone, and cone to cone is also available. It is ideal for chemical fiber yarns, fully drawn threads, and metal wires.

Main functions include computer-based control system, individual control for single spindle, automatic oiling device, automatic doffing device, anti-patterning device, yarn breaking auto-stop, constant length control, overfeed speed adjustment, etc.

| Number of spindles | Max. 60 spindle per set, 5 spindles per section |

| Bobbin length | Standard: 170mm, customized range: 170-280mm |

| Friction roller form/size | Flat tube Φ80 (large diameter end) ×220, inclined tube: Φ80 (large diameter end) ×220, conicity: 3.5°, customized for customers special requirements |

| Tube | Flat or inclined tube, depending on customer needs |

| Max. package diameter | ≤220mm |

| Power supply | 220V/380V 50HZ three-phase five little system, 120W per spindle |

| Dimension | 1454 (L) ×1000 (W) ×1700 (H)/Section |

| Weight | 380KG/section |

- Adjustable slow start, adjustable winding speed and automatic tension control device ensure the high quality of this winding machine.

- Fast winding speed offers one-time forming, uniform tension and excellent shape formation.

- The winder has compact structure and small footprint.