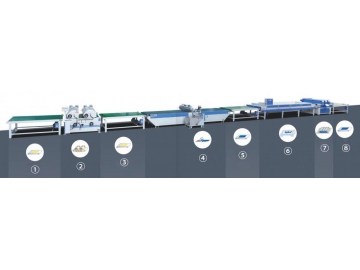

Automatic Tunnel Drying System

The automatic tunnel drying system utilizes an internal heating method with several vacuum chambers, heaters, temperature sensors and temperature control systems. This system is ideal for use with automatic load, discharge, drying, and cooling processes for lithium battery electrodes, cells, and separators.

1. Equipped with an automatic load system, tunnel vacuum oven, automatic discharge system and vacuum system, the automatic tunnel drying system automatically bakes and avoids man made errors, thus ensuring product quality.

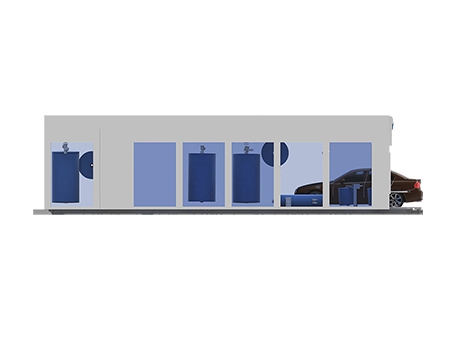

2. The production line includes the feed transition section, preheat section, preheat transition section, thermostatic section, thermostatic transition section, cooling section and cooling transition sections for baking. Changes between the sections is achieved via a power transfer device and a high vacuum sluice valve. The complete production line remains in a vacuum state to avoid secondary exposure to dampness and oxidation.

3. With the exception for loading and discharge needing dew point control, other parts of the line are not needed in order to reduce costs.

4. Heaters and temperature sensors are independently installed on the vacuum workspace surface. This assists in a stable temperature distribution and uniform heating.

5. The vacuum workspace connects the heater to the sealing sleeves and temperature sensors to KF to ensure an airtight structure. All cables are located outside the vacuum workspace in order to avoid discharge in a high vacuum state.

6. A targeted design can be provided according to customer requirements for an automatic tunnel drying system.