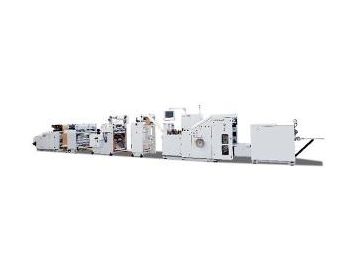

Automatic Roll-To-Roll Film Laminating Machine

Request a Quote

This paper and film laminating machine is suitable for laminating films with the same properties, such as BOPP, PET, CPP, PC, PVC laminated aluminum film, aluminum foil. The lamination speed is 120-150 meters/minute, and the mechanical speed is 160 meters/minute. (The lamination speed may vary for different materials and adhesives.)

Features

- The overall control of the machine is centralized and operated through a PLC touchscreen, providing easy operation, stable tension, and reduced waste.

- The main transmission adopts AC frequency vector control. The glue roller and hot drum are synchronized using swing arm control to ensure proper tension in the drying tunnel.

- One unwinding unit uses photoelectric web guiding system, and the other features dual-station web guiding structure. The cylinder automatically loads the materials, and the unwinding and rewinding tensions are centrally controlled by the PLC.

- The mesh roller applies the adhesive with a scraper, and the thickness of the adhesive can be adjusted as needed. The scraper pressure is controlled by dual cylinders, and the rubber roller is lifted by dual cylinders, allowing for adjustable pressure.

- Drying Tunnel Mechanism: The drying tunnel temperature is controlled by a three-section intelligent temperature controller, and the hot air drying system has four independent and constant temperature zones. The protective rollers and hot drum operate in synchronization. The tension control at the inlet of the drying tunnel is controlled by swing arms, and the composite side of the drying tunnel is equipped with an edge correction system to reduce film deviation during machine acceleration and deceleration. The drying tunnel is 9 meters long and equipped with an air top, featuring energy efficiency and waste reduction.

- The lamination drum is heated using thermal oil for uniform and energy-efficient heating. The pressure roller is controlled by dual cylinders, allowing for adjustable pressure.

- The machine adopts a linked rewinding device, and the rewinding is carried out by a motor with adjustable tension.

Specifications

| Model | SBYY800B |

| Number of laminated layers | 2 |

| Laminated width | 800mm |

| Diameter of the first unwinding roll | 600mm |

| Diameter of the second unwinding roll | 600mm |

| Adjustable line speed | 50-150m/min |

| Max. adjustable temperature of the drying oven | 75℃ |

| Max. adjustable temperature of the hot drum | 70℃-90℃ |

| Tension/stretch ratio | ≤1/1000 |

| Total installed power | 68kW |

| Machine weight | 5800kg |

| Machine dimensions | 10500×2860×3150 mm |

At CBADEN, we supply an extensive range of converting & printing machines and provide comprehensive services to accommodate customer's individual production demands.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos