SMF Closed Circuit Cooling Tower

SMF Closed Circuit Cooling Tower

1. Principle of Work

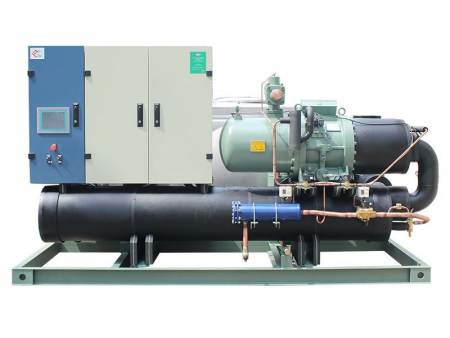

Developed on the basis of internationally advanced heat-exchange technology, SMF closed circuit cooling tower is apiece of highly efficient heat exchange equipment.

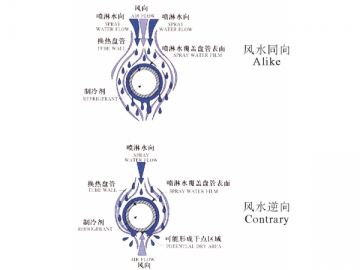

The working fluid is flowing inside the coils, which are enwrapped by spraywater on the outside. The heat of water is transferred by coils and becomes thesaturated vapor when meets the water and air. The heat is exhausted out of thecooling tower by the fan, and water is collected back to the bottom tank. Thespray water is cooled down via PVC radiation fin during the circulation processand flows in the same direction with the fresh wind. The coil mainly takessensible heat travel style. This is especially suitable for cooling high temperaturefluid.

(1). The cooled circulating water helps increase thetemperature difference between the water and the warm process fluid, whichresults in a smaller coil heat exchange size, fewer coil connections, and thusreduced weight. This feature further reduces thetendency to form scale on the coil since cooler water offers higher solubilityfor scaling.

(2). Parallel air and water paths minimize scale-producing dry spots that maybe found on the bottom of tubes in conventional cooling towers.

(3). The coil section of the closed circuit cooling tower dissipates heatthrough both evaporative cooling using the fresh air stream and, moresignificantly through sensible heat cooling using the pre-cooled circulatingspray water. Reducing evaporative cooling from coils helps to minimize thepossibility of forming scale on the coil surface.

(4). The circulating spray water falls from the coil to PVC heat exchangepadding where it is cooled by second fresh air stream using both evaporativeand sensible heat transfer processes.

(5). Water is pumped over the evaporative coil surface area at

2. Advantages

The closed circuit cooling tower provides manyoperational and maintenance benefits to the user by keeping the process fluidin a clean, closed loop.

(1). Protect process fluids from contamination.

(2). Maximize systemefficiency by reducing fouling.

(3). Reduce system energy costs.

(4).Reduce system maintenance costs.

(5).Provide reliable, efficient, year-round operation.

As a result, our SMF closed circuit cooling tower is a product of choice forusers.

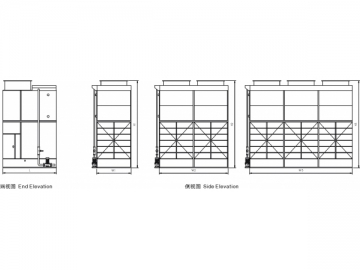

3. Parameters of SMF Closed Circuit Cooling Tower

| Model | Nominal flow rate (m³/h) | Fan power (kw) | Air flow (m³/h) | Water pump power (kw) | Spray water (m³/h) | Pipe-connecting size (mm) | Approx. weight (kg) | Dimensions L×W×H(mm) | |

| Shipping | Operating | ||||||||

| SMF-30 | 38 | 4 | 60000 | 1.5 | 45 | 65 (2) | 2950 | 3880 | 1850×2410×4225 |

| SMF-40 | 46 | 5.5 | 65000 | 1.5 | 45 | 80 (2) | 3150 | 4290 | 1850×2410×4225 |

| SMF-50 | 55 | 5.5 | 75000 | 1.5 | 45 | 80 (2) | 3680 | 5100 | 1950×3030×4265 |

| SMF-60 | 67 | 7.5 | 75000 | 2.2 | 65 | 100 (2) | 3850 | 5500 | 1950×3030×4265 |

| SMF-70 | 75 | 4(2) | 60000 (2) | 2.2 | 65 | 100 (2) | 4950 | 7980 | 3590×2410×4225 |

| SMF-80 | 96 | 5.5(2) | 65000 (2) | 3 | 95 | 125 (2) | 5280 | 8250 | 3590×2410×4225 |

| SMF-100 | 109 | 5.5(2) | 72000 (2) | 3 | 95 | 125 (2) | 5580 | 8900 | 3790×2610×4965 |

| SMF-125 | 135 | 7.5(2) | 75000 (2) | 4 | 125 | 150 (2) | 5750 | 9100 | 3790×2610×4965 |

| SMF-150 | 156 | 7.5(2) | 87000 (2) | 4 | 125 | 150 (2) | 6550 | 9850 | 3790×3030×4965 |

| SMF-175 | 182 | 5.5(3) | 65000 (3) | 5.5 | 165 | 175 (2) | 6890 | 10900 | 5330×2410×4825 |

| SMF-200 | 211 | 7.5(3) | 75000 (3) | 5.5 | 165 | 175 (2) | 7350 | 11200 | 5330×2410×4825 |

| SMF-250 | 260 | 7.5(3) | 87000 (3) | 7.5 | 210 | 200 (2) | 8860 | 12100 | 5630×2610×4965 |

| SMF-300 | 315 | 11(3) | 125000 (3) | 7.5 | 210 | 175 (4) | 10600 | 14100 | 6000×3200×4965 |

| SMF-350 | 359 | 7.5(4) | 100000 (4) | 5.5 (2) | 165 (2) | 175 (4) | 12500 | 17800 | 8050×3200×4965 |

| SMF-400 | 412 | 11(4) | 125000 (4) | 5.5 (3) | 165 (2) | 175 (4) | 13900 | 19900 | 8050×3500×4965 |

| SMF-500 | 522 | 7.5(6) | 87000 (6) | 7.5 (2) | 210 (2) | 200 (4) | 16900 | 23900 | 5630×5250×4965 |

Piping size andinstallation must be in accordance with good piping criterion. All pipingshould be supported by pipe hangers or other supports, not by the closedcircuit cooling tower. External shut off valves may also be required if thesystem design necessitates the isolation of individual tower cells.

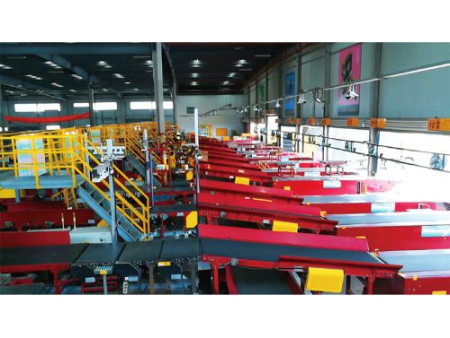

In general seasons,the performance of most closed circuit cooling tower will vary due to thechange of its environmental wet bulb temperature. Therefore, when the change ofenvironmental temperature leads to the difference of liquid temperature, inthis case, capacity control will be required.

Fan periodicity operation is the simplest method of capacity control for ourclosed circuit cooling towers, normally used in multi fan unit system or multicell unit system. In some circumstances of low requirement on outlet watertemperature control, fan periodicity operation can meet with temperaturecontrol requirement, and also, is easy to handle. Using two-speed fan can providesubstantial energy savings when compared to simple fan periodicity operation.

At below freezingambient temperatures, the closed circuit cooling tower can experience heat losseven when the circulating spray water pump and fans are not operating. Withouta heat load on the circulating fluid, coil freezing can occur even at fullflow. Protective measures are readily available to avoid potential freezingproblems. Where the system will permit, the best protection against coilfreezing is the use of an anti-freeze solution. When this is not possible, thesystem must be designed to meet the following conditions: Maintain a heat loadon the circulating fluid so that the temperature of the fluid leaving the coilwill not fall below7℃.

| Glycol (wt %) | 0 | 10 | 20 | 30 | 40 | 50 | 58 | 80 | 90 |

| Freezing point (℃) | -0.0 | -3.5 | -8 | -15 | -24 | -36 | -48 | -47 | -29 |

5.High Quality Parts

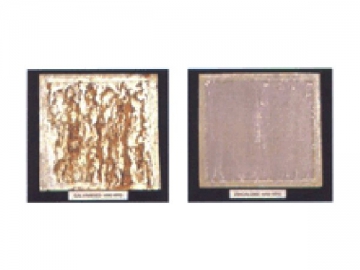

(1) Imported Galvanized Steel Sheet

The shell of thecooling tower uses imported galvanized steel sheet, which offers greatcorrosion resistance, heat resistance and aesthetic appearance. In addition,the galvanized steel sheet lasts 3-6 times longer than ordinary galvanizedplates.

(2) Electronic Scaling Apparatus

The enclosed circuit cooling tower isequipped with advanced electronic scaling apparatus, which can do antiscale, contaminantseparation, sterilization and algae removal through the use of electronic pulsetechnique. The only thing you need to do is Connect 220V power, and then itwill deal with the recycled water, which effectively prevents the formation ofdirt on both coil walls and padding.