Common Cleanroom Ceiling System

Common Cleanroom Ceiling System

MAX-CC Common Cleanroom Ceiling System

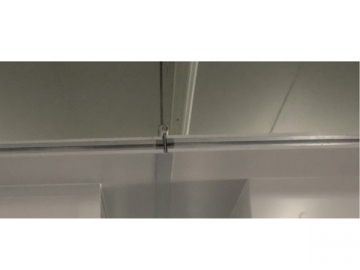

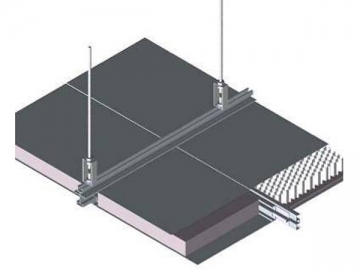

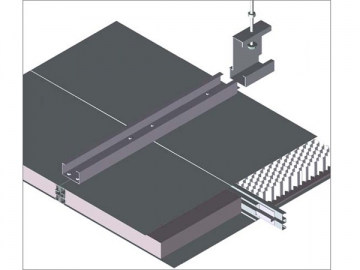

MAX-CC common cleanroom ceiling system which meets the GMP requirements of the pharmaceutical factory is widely used in the clean room of ISO standard class below 1000. It can be made of rock wool core material, honeycomb core, honeycomb core sandwiched into calcium silicate board, and etc. The ceiling system is invisible when applied to the clean room, ensuring the flatness and smoothness of the ceiling panel. Also, the ceiling panel can be easily cleaned, and no dust will be generated. MAX-CC common cleanroom ceiling system comes with three types like MAX-CC-A series, MAX-CC-B series, and MAX-CC-C series.

Parameters

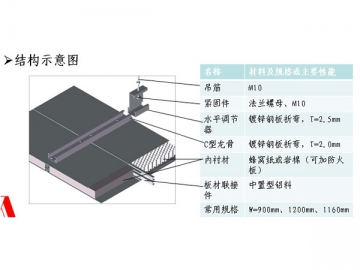

Name | Material & Size or Performance |

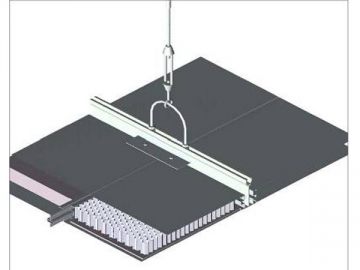

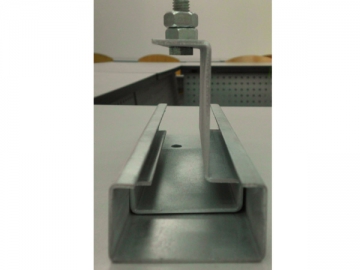

Steel Hanger | M10 |

Fastening Piece | Flange nuts、M10 |

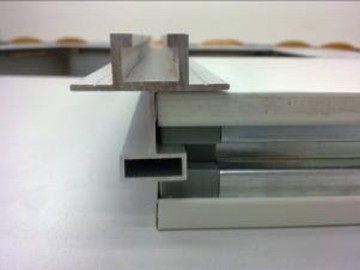

Level Governor | Galvanized steel sheet bending,T= |

C Shaped Keel | Galvanized steel sheet bending,T= |

Lining material | Honeycomb paper or rock wool (Fireproof board is optional) |

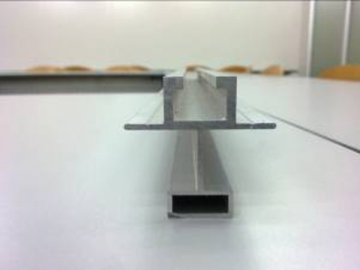

Panel Coupling Parts | Built-in aluminum material |

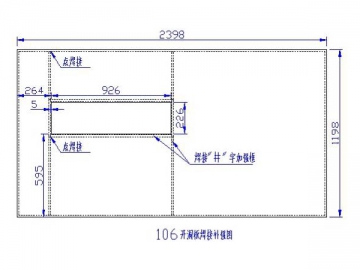

Conventional Size | W= |

MAX-CC-A

Hidden Type Self-folding C shaped Keel

C shaped ceiling system features convenient installation. When used in combination with the T-aluminum alloy parts, the ceiling panel can be easily dismantled. Our ceiling system has higher fire protection limit as compared to other aluminum alloy ceiling system. What’s more, the application of C type can ensure the uniform seam of the ceiling panel. Our recommended C type ceiling keel allows the ceiling panels’ seams to be adjusted uniformly.

MAX-CC-B

MAX-CC-C