Automatic Butyl Self-Adhesive Waterproofing Membrane Production Line

Request a Quote

Complete coating line for self-adhesive butyl rubber backing

The automatic butyl self-adhesive waterproofing membrane production line comes equipped with adhesive coating, film laminating, sand spreading, sand placement, sand recycling, material storage, automatic cutting, winding, and unloading. The specially designed applicating head ensures uniform gluing. The produced waterproofing membrane can be widely applied in construction, leak repair, sealing, wind power industry, battery, etc. industries.

Specifications

| Effective Coating Width | 1200-3000mm |

| Coating Weight | 80-500g/m² |

| Machine Speed | 1-30m/min |

| Power Supply | 380v ±15PHz |

Parameters can be adjusted according to specific customer requirements.

Features

- Automatic edge correction system, adhesive applicating pressure stabilizing system, as well as touch screen PLC control.

- Specially designed applicator head flow channel, ensuring uniform and precise application.

- Highly automated, convenient operation, labor-saving.

Frequently Asked Questions

A coating line refers to a series of one or multiple web coating equipment and related drying equipment that work together seamlessly to achieve the entire process of coating on flexible substrates. This includes unwinding and rewinding, cutting, drying, and cooling units, integrating all functions in one system.

Yes, a web coating line can include different types of coating equipment to perform coating processes on different parts of the product.

With coating technology, various levels of smoothness can be achieved, whether it's transparent or colored, matte, semi-gloss, or glossy finishes. Additionally, since a web coating line consists of multiple equipment such as coating equipment, drying equipment, and conveying machines, it can not only accomplish surface treatments for high surface wear resistance but also perform further processing on the substrate.

In order to achieve high-quality coating on straight edges with radii and non-flat edges, vacuum technology is required.

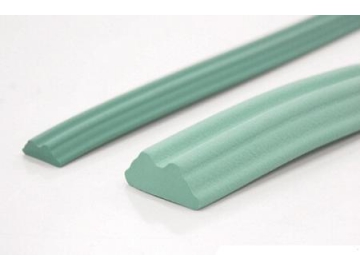

If the edge is straight and has a smaller radius, roller coating technology would be more suitable.

If the edge is straight and has a smaller radius, roller coating technology would be more suitable.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos