Best Practice

1. Client from Argentina, in the end of 2011

Products

1. Spindle-less veneer lathe

2. CNC router

3. Customized production line for plywood splicing

Customer requirement

1. The wooden core has a large diameter of 150mm after being processed by the single spindle veneer lathe; and the spindle-less veneer lathe can further process the wooden core and minimize its diameter to 30mm; the wooden core having small diameter can be used to produce the core veneer with the diameter of about 3.5mm.

2. This client produces wood floor for Mercedes-Benz motor homes; we adopted the CNC router to shape the plywood based on the AutoCAD drawing provided by client.

3. We glued and hot pressed the sawed plywood, and spliced the plywood into the required length.

Cooperation

This client is from Iguazu, Argentina. He came to know us by a friend met online and visited China after recognizing that our quotes accounts for 1/3 of that of similar products in Europe. He decided to cooperate with us after investigating three factories in Jiangsu Province. We got all the required woodworking equipment ready and shipped them to Buenos Aires, Argentina within two months after receiving the order. At the beginning of the second year (2012), we sent an engineer and an account manager speaking Spanish to Argentina to provide our client with installation and commissioning service. Our client was very satisfied with our equipment and service; the same day, he took the products manufactured using our equipment to meet his customers in Buenos Aires and has not received any complaints about quality problems since then.

2. Client from Australia, at the beginning of 2013

Equipment

4-roller glue spreader with customized length of 2800mm

Customer requirement

Our client from Australia needed a glue spreader with longer roller of 2800mm (the regular length is 2700mm) to expand the production.

Cooperation

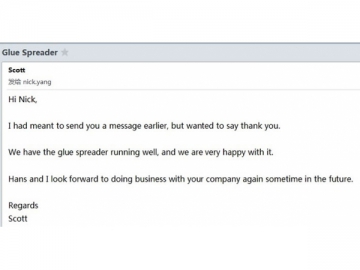

This partner is located in Brisbane, Australia. He learned some Chinese suppliers including us via the Internet and came to China to have a site visit. After investigating us in Shanghai and several other suppliers in Shandong Province, he finally chose us because of our innovative and reasonable product structure. Superior to the ordinary chain type structure that is complex and hard to maintain or repair, our shapely glue spreader consists of a gearbox and a universal joint transmission. Moreover, we had a smooth communication and our customization service can meet all of his special requirements, such as longer roller length, higher overall height, separated control box, specially threaded upper and lower rubber rollers, changed motor voltage, etc. We shipped the customized equipment within 50 days after receiving the order; and we received a letter of acknowledgment from our client five months later. It reads as follows:

3. Client from India, since the end of 2010

Product:

Customized hot press molds with special specifications and shapes

Customer requirement

To customize hot press mold according to client’s drawing

Cooperation

This customer is located near Mumbai, India. He got to know us via a friend and visited us in China afterwards. In our first collaboration in early 2010, he only asked us to process the base materials for molds and do not require assembly and finish machining. In our second cooperation, after inspecting one of our suppliers located in Kunshan City, he gave us a positive evaluation and required us to manufacture molds and control the error less than 0.1% in mold assembly; the biggest format of mold is 2806×2908mm. To ensure accuracy, we use our own CNC machine to process the mold to achieve critical size. Our client has repeatedly expressed his satisfaction towards our products and service in the e-mail and face to face communication.

4. Client from Indonesia, at the beginning of 2010 and the mid of 2013

Products

1. 16-layer veneer drying machine with automatic loading and unloading mechanism

2. Single spindle veneer lathe

Customer requirement

Single spindle veneer could be used to process the wooden core, and drying machine could be used to dry the processed core veneer.

Cooperation

This client is located in Sumatra, Indonesia. He met us via friends and came to visit China at the end of 2009. After three months’ inspection, he decided to purchase two of our devices beforehand: one veneer peeling machine and one press type veneer dryer. We sent our engineers to carry out installation and commissioning for client; and we received positive recognition. 2 years later, this client purchased the same hot press dryer again and installed it by themselves.

5. Client from Ecuador, in the end of 2013

Products

1. Processing equipment for wood floor: double end milling machine and trim saw;

2. The painting line for wood floor consists of UV dryer, roller glue spreader, belt conveyer and dust cleaner.

Customer requirement

1. Our client imports wood materials from Peru and carry out production of wood floor in his factory. He required a double end milling machine to slot both ends of the wood floor for splicing; also, he needed new trim saw to cater to the changed product specification.

2. The equipment could realize painting on the wood floor and achieve self-commissioning during the process of production. We worked out several alternative plans according to customer needs.

Cooperation

This customer is located near the mountain area of southern Ecuador. He learned us via the website and accepted our quotes after a few months’ communication and negotiation with us. The plywood machineries were shipped to his factory in May, 2013. We sent two engineers and one account manager speaking Spanish to Ecuador to install and debug the equipment as well as train local workers. After 10 days of installation and commissioning, and 4 days of training, our client is capable of continuously carrying out production in his factory. He is very pleased with our products and our services and intended to cooperate with us again to develop new projects.

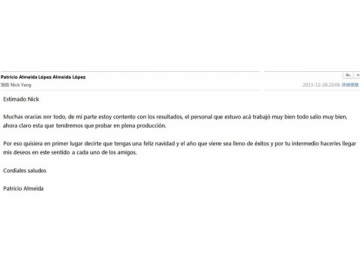

Here is his letter of acknowledgement: