Components

Components

The hoisting mechanism is made up with a motor, a brake, a reducer, a winch drum and a hoisting height limiter. Installed at rear of the balance arm, it is driven by a three-speed motor. Operator can use the change-over switch on the manipulation platform to obtain ideal hoisting speed and high accuracy slow positioning.

The motor can be installed vertically or horizontally. Different rope capacities are available. The speed regulating system is made up with two three phase winding asynchronous motors, which interact with each other through gear transmission devices and cascade speed control circuits. The hoisting mechanism of flat top tower crane features wide speed range, high speed hoisting, slow positioning, smooth speed change and high efficiency. It has an L-shaped layout and it comes with a winch drum with double fold line groove to ensure large rope capacity and prevent steel wire from messing up during multi-layer winding. It is extensively used for construction of high-rise buildings and hoisting of large equipment and components.

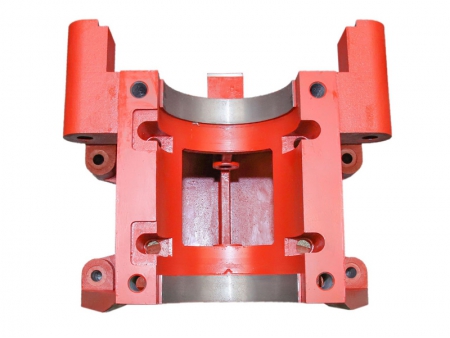

The slewing mechanism consists of a three phase asynchronous motor, a hydraulic coupler, a disc electromagnetic brake and a reducer. It features compacting structure, smooth operation, high efficiency transmission, lower noise, long lifetime and high reliability

The cabin trolleying mechanism is developed with the advanced technology at home and abroad. It consists of a three-phase asynchronous motor, a built-in planetary reducer, a reel and a rack. The motor have three speeds, which can be adjusted with voltage regulation along with control of its eddy current brake. The motor comes with a disk electromagnetic brake, which leads to smooth speed variation during startup and brake, reliable and safe brake and accurate positioning. The trolleying mechanism is suitable for MC series flat top cranes. It can substitute imported counterparts.

Developed with foreign advanced technology, the walking mechanism is made up with a three-phase asynchronous motor, a reducer, a walking trunk and walking wheels. The speed of the motor, low or high, is adjusted by changing the pole number. Equipped with double power-off electromagnetic brakes, the motor enables buffered startup and brake, steady speed change, reliable and safe brake and accurate positioning. The mechanism is suitable for variety of flat top tower cranes and it can substitute imported counterparts. In addition, it can work with a variable-frequency and variable-speed motor.

Made of plate structure, the driver cabin is installed at the front end of the platform at the right side of upper bracket. Large windows are available on all sides of the cabin. The front window can be opened. The cabin features full view, beauty and comfort. There is an interlock manipulation platform inside of the cabin. Air conditioner is also available if required.

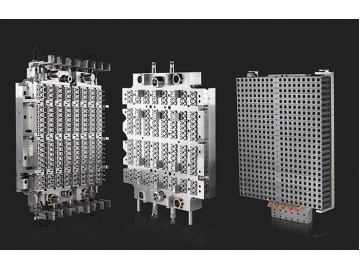

Serving as an electrical control system solution, the control cabinet is developed by us through absorbing and improving of foreign advanced technology. The control cabinet features high running speed, wide speed range, high efficiency and safe and reliable operation. It can be equipped with frequency converters if required.

The flat top tower crane is equipped with necessary safety devices including annular weight limiter, arch plate moment limiter, amplitude limiter, hoisting height limiter, slewing limiter and anemometer.