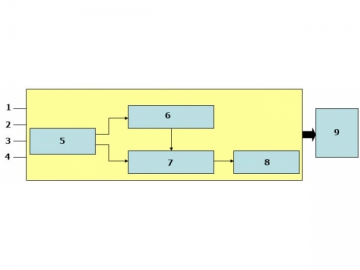

DRL Drive Design

Drive design is an essential part in the development of daytime running lights, and our technical advantages are displayed here. It is the reasonable drive design that ensures both a safe and stable performance of our DRLs.

| 1. Ignition Wire 2. Small Lamp Wire 3. Battery - | 4. Battery 5. Power Input Unit 6. Micro Control Unit | 7. Power Drive Unit 8. Power Output Unit 9. LED String Light |

Power Input Unit

The power input unit is directly connected to the car battery as the power input source. As different functions require, we cab provide large and small light dimming function lines, which can be automatically lit upon the ignition.

To prevent damage to the DRL drive due to incorrect wiring, a protection circuit is designed for the drive. No matter how many lines are connected, the drive won't burn, and will still work correctly and normally when incorrect wiring is corrected.

The engine starts instantly in conjunction with a high voltage pulse, which is higher than the rated voltage. Due to that, we have also designed a surge protection circuit to improve the reliability of the drive for long-term use and its ability to adapt to different car models.

The battery input line is fitted with a fuse to prevent simple drive failures from causing accidents, as set by UL regulations.

Power Drive Unit

The power drive unit is a power conversion area, which converts the car’s battery power into a constant current LED driving force. The constant current drive can ensure a consistent LED brightness and extend the LED service lift. It also improves power efficiency and reduces heat.

In order to increase the power efficiency, the power drive unit uses an imported, high-quality power chip, saving up to 90% in power efficiency, and ensures the long-term working reliability of the drive.

Usually, switching power supplies on and off creates a lot of noise, which can interfere with other electronic modules in the car, such as the car radio. Because of that, we optimized the power circuit design and layout to keep the noise at a minimum.

The power dive unit comes with the greatest compatibility to meet the requirements if a variety of LED auto lights. A single drive can drive 6 to 16 white LED string lights, covering nearly any application for DRLs.

Micro Control Unit

The micro control unit is designed to monitor batter voltage and various functional signals such as dimming signals and ignition signals, and depends on those signals to control the power drive unit. It can all be compressed into the “brain” of the DRL drive.

For better accuracy in signal monitoring, we added a digital filtering procedure to the chip program to enhance the anti-jamming capabilities. As long as the drive is connected to the batter, the micro control unity will be in a monitoring status. The reliability of the unit is critical, therefore, the circuit in

In addition, the micro control unit uses imported micro-controller chips, and the internal procedures are encrypted to avoid being copied.

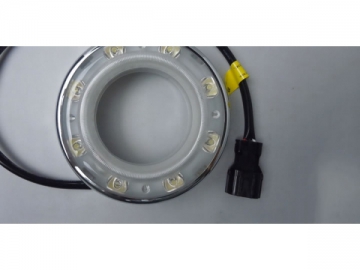

Power Output Unit

Finally, through the power output unity, the DRL drive signal will reach the LED string lights. The output unit has an output filtering function to reduce the output current ripple. In addition, LED open circuit protection is specially designed for the constant current drive to make sure that the drive circuit will not burn when there is no LED connection.