Geomembrane Installation

Preparatory Work

1. Before applying a geomembrane liner, the surface soil of a pond, dam or water channel should be leveled and tamped. Construction workers should make sure that the foundation is stable and there aren't abrupt changes in the slope.

2. Dig a U-shaped anchoring trench about 400x400mm to place the geomembrane liner in. The four corners should be rounded to keep the liner from bending.

3. Prepare sandbags or other items used for tamping or anchoring ahead of time to protect the impermeable membranes from damage caused by heavy winds or bad weather.

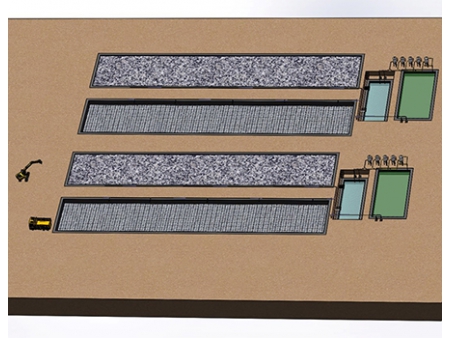

4. Draft a blueprint of the construction site, including length or area of any ponds, dams, or water channels so the drawing covers the direction, position, and sequence of liners.

Geomembrane Laying

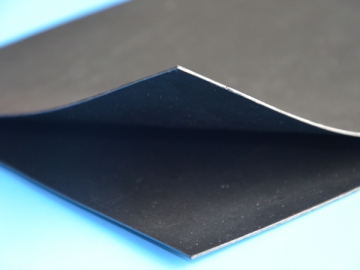

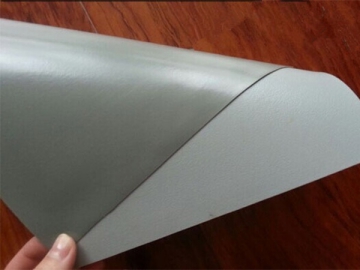

1. How much of the geomembrane liner you can lay down depends on the amount that can be welded within the workday. Make sure the liner is intact before laying down.

2. Follow the blueprint drafted earlier. Overlapping seams should be minimized to avoid irregularly-shaped or crossed welding seams.

3. The geomembrane should be laid starting from the lowest place and going to the highest place. There should be at least 1.5m of liner extension both at the top and bottom of the slope.

4. The geomembrane liner should be tightly fixed onto the soil's surface without folds or creasing. If the geomembrane lining system will be connected to a building foundation, carefully flatten the liner for best effects and tight sealing.

Welding

1. Wipe the geomembrane liner, especially the lapping zone, clean of dust before welding for the best welding quality.

2. Perform a welding test by using a two-way welding machine and two 1m pieces of a geomembrane liner sample. If the liner won't easily tear after welding, then you're ready to weld.

3. After starting the two-way welding machine, wait until it is sufficiently preheated. During welding, the liner should be quickly fed into the machine, adjusting the speed as necessary.

4. When the slope gradient is larger than 1:3, constructors should use a rope ladder and safety belt.

Anchoring Trench Backfilling

After the impermeable membrane is laid, refill the anchoring trench with soil. As the soil may slide down due to gravity, take precautions to ensure the stability of the construction site.