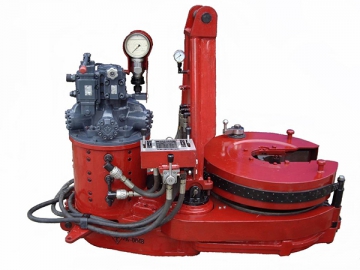

ZQ203-125Ⅱ Drill Pipe Tongs

Model ZQ203-125II drill pipe tongs are widely used in oil well drilling servicing operations. Their open-throat design allows the tongs to freely disengage the two arms from the pipe being clamped.

This series of gripping unit brings together the spinning wrenches and torque tongs, which can be used in place of cathead, manual tongs, and spinning rope. It is safe and convenient to use with little effort. Its high working efficiency has made it well suited for use in frequent, long-term oil well drilling applications.

Mode ZQ203-125II offers significant improvements in torques and structural design over the original ZQ100 series. Door interlock is provided as safety feature that integrates the lower tongs, door latch, and tongs traveling mechanism. The whole pneumo-hydraulic assembly improves the mechanical properties.

Features

1. Upper tongs are constructed in one piece with lower tongs. Using this integrated tongs design avoids the possibility of bending the drill string even when the tongs are operating at high torque. It also prevents the drill pipe from sliding out of the tong

2. Movable tongs design simplifies the lifting mechanism. Self-aligning open throat ensures a tight, reliable grip onto the drill string.

3. Strengthened tong body and automatic door are connected to manage clamping force and movement, ensuring minimal deformation when the tongs are operating at high torque.

4. Unique to the tong head is the ramp and plug that allows easy, convenient assembly, disassembly, and maintenance.

5. The drill pipe tongs use a pneumatic tire friction clutch to shift gears. This allows the torque and speed to be easily controlled. The highest torque is available in both forward and reverse gears.

6. Driven by a pneumatic cylinder, the drill pipe tongs are be transported to any work site easily and effortlessly without the need of manual pulling or pushing.

7. Both the upper and lower pipetongs use brake bands and clamping cylinder to carry out operations. They both have simple structures.

Technical Parameters

1. Hydraulic System

Rated Flow Rate: 114L/min(30gpm)

Maximum Operating Pressure: 20Mpa(2900psi)

2. Pneumatic System

Operating Pressure: 0.5-0.9Mpa(75-135psi)

| Flow Rate | Tong Head Rotational Speed r/min | ||

| L/min | gpm | High Gear | Low Gear |

| 114 | 30 | 40 | 2.7 |

| 100 | 26.3 | 35.1 | 2.4 |

| 90 | 23.7 | 31.6 | 2.1 |

| 80 | 21 | 28 | 1.9 |

| 70 | 18.4 | 24.5 | 1.7 |

| 60 | 15.8 | 21 | 1.4 |

| Hydraulic System Pressure | Torque in High Gear | Torque in Low Gear | |||

| MPa | psi | N·m | ft·lbf | N·m | ft·lbf |

| 20.0 | 2900 | 12500 | 9220 | 125000 | 92200 |

| 17.0 | 2465 | 10000 | 7375 | 100000 | 73750 |

| 15.5 | 2175 | 9300 | 6855 | 90500 | 66750 |

| 13.0 | 1885 | 8500 | 6265 | 81100 | 59815 |

| 11.0 | 1595 | 7700 | 5675 | 66100 | 48750 |

| 9.0 | 1305 | 5700 | 4205 | 53900 | 39755 |

| 7.0 | 1015 | 3900 | 2875 | 41700 | 30755 |

| 5.0 | 725 | 3070 | 2260 | 29500 | 21750 |

5. Suitable Pipe Diameter Range

a. Types of jaw plates: 8", 51/2", 5".41/2", 31/2"

b. Suitable string pipes

8" drill string φ203-φ193mm(8-7.6 in), 51/2" couplers on the drill string φ178 –φ168mm (7-6.6 in), 5" couplers on the drill string φ162 –φ152mm (6.3-5.9 in), 41/2" couplers on the drill string φ146 –φ136mm (5.75-5.3 in), 31/2" couplers on the drill string φ121 –φ111mm (4.75-4.3 in)

c. Allowable wear loss for couplers: 10mm(0.4 in)

d. Allowable eccentric wear loss for couplers: 3mm(0.12 in)。

e. Total length of male and female couplers: 420mm(16.54 in)

6. Other Parameters

a. Transfer distance: ≤1500mm(59 in)

b. Rotational angle of door latch: 90°

c. Rotational angle of driver plate: ≥75°

d. Drill pipe tongs dimension and weight

Power tongs dimension: L×W×H=1720×1050×1750mm(68×41×69in)

Power tongs weight: 2600kg(5730 lb)