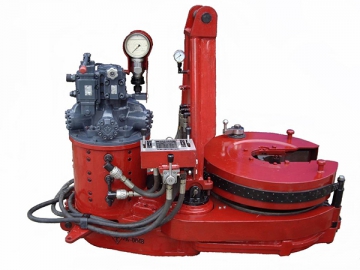

ZQ203-100Ⅱ Drill Pipe Tongs

Model ZQ203-100II drill pipe tongs were formerly known as Q10Y-W pneumo-hydraulic tongs. Today these tongs are commonplace in oilfields, where they are used to spin up the drill pipes or apply final makeup torques to them.

The open-throat design allows the tongs to freely disengage their two arms from the drill pipes. Using this gripping tool to make up or break out drill pipes eliminates the need for cathead, manual tongs, and spinning ropes. The tongs actually brings together the spinning wrenches and torque tongs into one piece of equipment.

Features

1. Except the hydraulic motor, all the other parts of our drill pipe tongs are pneumatically operated. In this regard, the tongs can have simplified hydraulic system.

2. Upper tongs are constructed in one piece with lower tongs. Using this integrated tongs design avoids the possibility of bending the drill string even when the tongs are operating at high torque. It also prevents the drill pipe from sliding out of the tong dies.

3. Movable tongs provide for ease of drill pipe lifting. Install a set of pulleys on the drill rig. One end of the steel rope is attached to the tongs while users use their hands to pull the other rope end for lifting height adjustment.

4. Self-aligning open throat ensures a tight, reliable grip onto the drill string.

5. Driven by a pneumatic cylinder, the drill pipe tongs are be transported to any work site easily and effortlessly without the need of manual pulling or pushing.

6. Simply hit the reset button, and the drill pipe tongs would automatically align its openings. This clamping device can quickly switch from the make-up motion to break-out.

7. Torque and speed control allows the drill pipe tongs to give the maximum torque or rotating speed in both forward and reverse rotations.

8. Both the upper and lower tongs adopt the brake bands and clamping cylinder to ensure a tight grip onto the drill pipe. Their structures are rather simple.

9. Door frame is used to prevent the tong head from deforming when the tongs are operating at high torques between 75KN and 100KN.

10. Hydraulic lifts allows the tongs to adjust their height.

Technical Parameters

1. Hydraulic System

a. Rated Flow Rate: 114 l/min

b. Maximum Working Pressure: 16.6MPa

c. Motor Power (on Electric Drive): 37kW

2. Pneumatic System

Working Pressure: 0.5-lMPa

| Flow Rate | Rotational Speed r/min | |

| L/min | High Gear | Low Gear |

| 114 | 40 | 2.7 |

| 100 | 35.1 | 2.4 |

| 90 | 31.6 | 2.1 |

| 80 | 28 | 1.9 |

| 70 | 24.5 | 1.7 |

| 60 | 21 | 1.4 |

2.Tong head torques are measured at different hydraulic pressures, under the following assumptions.

a. The brake brand produces a torque of 1000 N·m. This torque influence has been considered in Figure

b. The rotational inertia tends to increase the make-up torque while friction reduces that torque. To simplify calculation, the friction force and inertia force have offset each other. In fact, even at high gear ratio, the motor can produce enough torque to tighten up the drill string.

| Hydraulic System Pressure MPa | Torque N·m | |

| High Gear | Low Gear | |

| 16.6 | 10000 | 100000 |

| 15.0 | 9300 | 90500 |

| 13.0 | 8500 | 81100 |

| 11.0 | 7700 | 66100 |

| 9.0 | 5700 | 53900 |

| 7.0 | 3900 | 41700 |

| 5.0 | 3070 | 29500 |

5. Suitable Pipe Diameter Range

a. Pipe Diameter Range for Jaw Plates: φ127-φ203mm

φ203(8″ Drill String), φ178(51/2″ Drill String ), φ162(5″ Couplers on Drill String), φ146(41/2″Couplers on Drill String), φ127(31/2″Couplers on Drill String)

b. Allowable wear loss: 20mm

c. Allowable eccentric wear: 5mm

d. Minimum Length of Male or Female Couplers: 420mm

6. Pneumatic Cylinder

a. Maximum Stroke: 1500mm

b. Maximum Push Force: 2360N(P=0.6MFa)

c. Maximum Pull Force: 1710N(P=0.6MPa)

7. Lifting Distance: 0-485mm

8.Power Tongs Dimension and Weight

a. Drill Pipe Tongs: L×W×H=1720×1000×1615mm(Including the height of lifting assembly)

b. Oil Tank: L×W×H=1720×1060×1010mm

c. Power Tongs Weight: 2400kg

d. Total Weight: 4000kg(including the oil tank and power tongs)