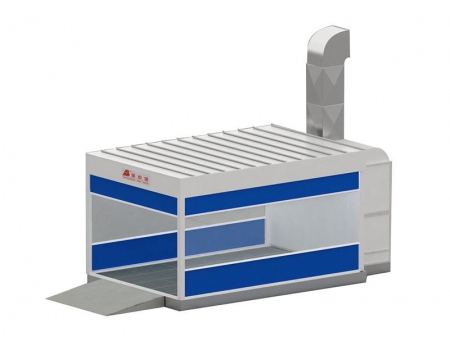

6600 Prep Station

Request a Quote

List of Configurations

| Product Name | Prep Station | |||||

| Product Model | BZB-6600 | |||||

| Product Configuration and Technical Parameters | Internal Dimension | 6400×4000×2650 | External Dimension | 7650×4106×3380 (without ramps) | Total power | 9kW |

| Cabin System | 1. At the top of our 6600 prep station, the plenum chamber is formed by cold-rolled steel plates. The roof panel is made of galvanized steel sheets. 2. On the front end and both sides of equipment, we put to use the electric roller shutter, which is remotely controlled and operated conveniently. 3. On the rear side of the wall, there are EPS heat-retaining panels of 50mm thick. 4. The exhausting basement is an integrated anti-corrosive system. The walking basement consists of checkered plate and high strength grids. 5. The whole structure of basement features light weight, novel design, and gorgeous appearance. It gives ultra high strength, stiffness, stability, and shock resistance. | |||||

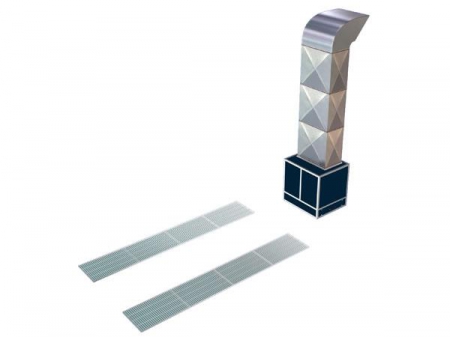

| Air Circulation System | 1. The YDW series double-inlet centrifugal fan is formed of compression molded galvanized plates by adoption of Siemens technology. Made by a fan specialist, it features great air capacity, low noise, and superior temperature resistance. Its specifications can be seen as follows. Model : YDW-4.5AL1 Air Capacity: 12,000m3/h Total Pressure : 800Pa Rotational Speed : 900rpm Power: 4kW Quantity : 2 set (inlet and exhaust fans) 2. Fan Cabin: This cabin consists of alloy frame and steel plates. It is firm, reliable, gorgeous, and also convenient for maintenance. | |||||

| Air Purification System | 1. The high-quality filter screen is produced in Italy. This multi-layered structure is fixed at the bottom of the plenum chamber, and supported by roof mesh. 2. The roof mesh is constructed from C section steel, which can resist corrosion. 3. The ceiling filter can be replaced easily. It can successfully catch the granules with the diameter of over 5μm. | |||||

| Environmental Protection System | 1. The floor filter under the grille of the return air duct serves to seize large dust particles. 2. The glass fiber filter is mounted inside the exhaust cabin for catching the remaining dust particles. | |||||

| Lighting System | 1. Lighting sets are installed on the top of the ceiling. Totally 32 pieces of 36W Philips tubes are mounted to provide the room with 900-lux light output. The light is soft, and the illumination is bright and even. 2. The ballast is used for special purpose. It features stable performance and long service life. | |||||

| Electric Control System | 1. This system consists of superior-quality electronic components. All operational processes are set to be accomplished for only once. 2. The main circuit features multi-protection, such as excess current, excess load, short circuit, and phase failure, among others. 3. This system also comes with the assembled working switch, lighting switch, emergency stop switch, failure alarm, and much more. | |||||

Related Names

Automotive Paint Finishing Booth | Automotive Refinishing Booth | Mobile Spray Booth

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos