Process

Pioneer is your trusted manufacturer of OEM parts. We hold best-in-class CNC custom machining and fabricating capabilities and extraordinary price advantages. Custom parts from Pioneer are manufactured through a series of processes including cutting, turning, milling, boring, grinding, electrode cutting, surface treating, marking, testing and warehousing.

1. Cutting

We have sawing machine, flame cutter, water jet cutter and laser cutter equipped for precision cutting. Among them, the plate cutting thickness of water jet cutter is up to 40mm and laser cutter can cut 25mm, with accuracy reaching ±0.05.

- Sawing Machine

- Flame cutter

- Water Jet Cutter

- Laser Cutter

2. CNC Turning

As for turning process, we have high precision CNC turning lathe with inclined guide rail, turning center and common turning lathe. The maximum turning diameter gets up to 1000mm and length to 4000mm. Maximum accuracy is ±0.005.

- CNC Turning Lathe

- Common Lathe

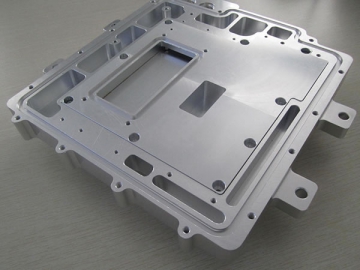

3. Milling

During milling process, we use 5-axis gantry machining center (Machining range: 4000 x 2800 x 500mm; Maximum accuracy: ±0.02), 4-axis machining center (Machining range: 1500 x 1000 x 800mm; Maximum accuracy: ±0.01) and 3-axis machining center (Machining range: 1000mm x 600 x 600mm; Maximum accuracy: ±0.01). In addition, we also introduce some milling machines, drilling machines, etc.

- 3-Axis Machining Center

- 4-Axis Machining Center

- 5-Axis Machining Center

CNC Boring Machine

4. Boring

We employ CNC boring machine to realize the maximum boring diameter of 800mm and maximum accuracy of ±0.01. Additionally, we also use deep hole drilling machine to reach the maximum drilling depth of 3000mm and maximum diameter of 300mm.

Grinding Machine

5. Grinding

During the grinding process, we use different grinding machines to reach most precise machining, including flat grinding machine (Maximum machining range: 2000 x 1500 x 100mm, Maximum machining precision: ±0.005, Maximum planeness:0.005), and internal and external grinding machine (Maximum machining length: 1500mm, Maximum machining diameter: 300mm, Maximum machining accuracy: ±0.003, Maximum concentricity: 0.005).

Honing Machine

6. Honing

Honing machine is also equipped to enhance machining precision. The maximum honing length is 2000mm, maximum honing diameter is 300mm and maximum precision is ±0.01.

7. Heat Treating/ Surface Treating

We build painting room and sand blasting room to do surface treating. Other surface treating processes are outsourced.

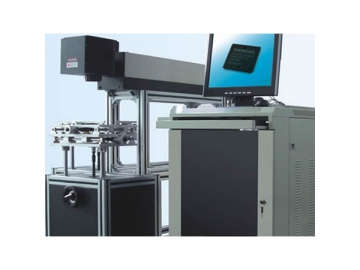

Laser Marking Machine

8. Marking

Laser marking machine, pneumatic marking machine and manual carving device are used to carry out quality marking on the made to order parts.

9. Testing

A number of high precision testing devices are equipped to perform rigorous and accurate testing, such as CMM (max. accuracy: 0.003mm/m), profile projector (max. accuracy: 0.005), hardness, surface roughness tester, automatic height tester, material analyzer, 3-clamp micrometer, etc.

10. Warehousing

After testing, qualified products can be stored in warehouse. Materials needed for warehousing include process flow sheet, dimensional test report, surface treating report, material report, etc. Common parts are packaged separately.