Surface Strengthening of Castings

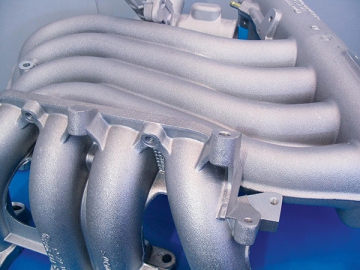

Our shot blasting machines and metal abrasives are commonly adopted for the desanding and descaling of steel castings and iron castings.

In fact, almost all castings (like steel casting, grey iron casting, nodular iron casting, malleable iron casting, etc.) require shot blasting since this treatment not only removes sand and mill scale, but is also a must before testing the quality of castings. For example, if a gas turbine housing is going to receive NDT, it must be shot blasted in advance so as to get reliable test result.

Shot Peening for Crank and Connecting RodRecommended Model

Composed of blast wheel, turbine, belt pulley, V-belt and bed plate, the blast wheel assemblies are installed on the side walls of blast cabinet, and there are 6 of them in total. Their position and angle are calculated by 3D dynamic simulation to offer full surface cleaning with minimized dead zone.

The Q15GN and Q28GN rubber belt blasters are used to remove oxidized layer and other contaminants from surfaces of castings, forgings and weldments, and they are also applicable for other metal parts, such as aluminum castings, nonferrous parts, hard-to-clean work pieces, easy-to-tumble work pieces, castings with small cavity depth, non-brittle metal components, etc.

The spinner hanger shot blasting machine offers a reliable blast cleaning solution for different kinds of work pieces, and it is typically designed to handle medium and large components that cannot be tumbled in bulk loads. In addition, with a compact structure, high productivity and no foundation pit, this surface treatment equipment has been extensively utilized in various industries.

This rotating barrel wheel blast machine makes its barrel rotate and swing when propelling abrasive media, so work pieces inside the barrel are tumbled sufficiently without part-to-part collision, thus realizing uniform coverage, short cleaning time and high working efficiency.

Our wire mesh shot blast machine takes advantage of a wire mesh belt conveyor to transport work pieces into the fully enclosed blast chamber, and then the blast wheel assembly uses a high-speed rotating impeller to accelerate and spray abrasives onto the surface of work piece to realize thorough surface cleaning. In addition, this metal surface cleaning equipment is applicable for flat shaped castings, forgings and structural parts.