Spindle Seals for Tunneling Shield

If you’ve been up close enough to a tunneling shield, you will see how much sand, gravel, or mud is involved in the tunnel boring process and how dangerous it would be should any of it get inside the shield.

The spindle seal is designed specially to prevent sand or particulate matter from entering the shield through the gap between the spindle and the housing which might further result in the wear or failure of the transmission system or main bearing. In the worst-case scenario, the entire tunnel boring system would simply break down. That is why the spindle seal is so important for the tunneling shield, as it may affect the service life of the machine and the progress of tunneling project.

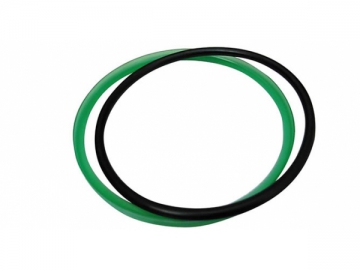

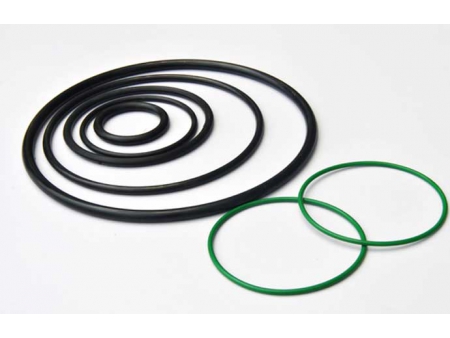

Our spindle seal is built to your practical needs at the tunneling job site. This multi-lip seal, though simple in construction, lasts long and works reliably. It is out in the field running day in and day out delivering solid performance on even the toughest terrain.

This sealing device is now on promotion, and covered by patent number 201320079650.0.

Operating conditions: tunnel boring

Operating pressure≤5MPa

Operating temperature: 10°C~75°C

Operating media: water, sand, gravel, slurry, grease

Material: filled PTFE compounds

Design standards: API, GB/T3672.1-2002

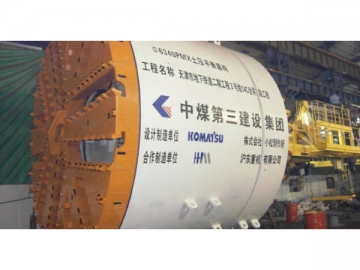

Tunneling shield