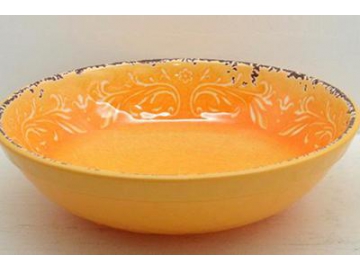

Custom Waterslide Decals for Variety of Applications

Request a Quote

Step 1: Soaking

- After cutting the waterslide decals and tearing off the release papers, soak the decals in water. They must be completely soaked in the water, in case patterns and the waterslide decals are difficult to separate.

- They generally need to be soaked for 5-10 minutes.

- Maintain an appropriate water temperature. Temperature will affect the effectiveness of the waterslide decals. Generally, when the temperature is low, the decals will be fragile and can crack after application. Therefore, the users can soak the decals in hot water or water with alcohol or softeners added. The proportion can be determined according to the situation during printing.

Step 2: Printing

- Put the soaked waterslide decals on the surface of the and make sure the waterslide decals are flat on the surface in case the decals wrinkle and the water cannot be wiped off completely.

- Scrub with gloves or cloth made from cotton and chemical fiber to completely wipe off the water and bubbles between the surface and the decals. If bubbles are left, there will be blisters during the baking process.

- If the surface is not flat, the users must ensure the are close to the surface of the item in order to prevent discoloration in the uncompacted part after drying.

- During printing, if the waterslide decals cannot be pressed in an uneven surface, the users can use a hot air blower while pressing.

Step 3: Baking

- To improve the adhesion, the object should be baked in a curing oven. The duration and temperature of baking have a great influence on the strength of the adhesion. The temperature and duration settings are based on the highest temperature resistance of the plastic. The higher the temperature, the better the adhesion.

ABS: Baking temperature 65-75 ℃ Duration 25 minutes

Metal: Baking temperature 75-85 ℃ Duration 20 minutes

Glass: Baking temperature 130 ℃ Duration 20 minutes

In addition, the plastic pots for holding object should be resistant to high temperatures in case the shapes of the plastic pots are changed during baking and damage the plastic.

- It is best to bake after 12 hours after the workpieces are attached to the waterslide decals. The time can be shortened appropriately in summer and lengthened appropriately in winter. This is to prevent the occurrence of blisters after baking due to water and bubbles.

- Make sure there is a proper spacing between the workpieces during baking in case the waterslide decals stick to each other.

- After baking, adhesion test and packaging process should be performed when the workpieces are completely cooled.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos