High-Speed Metal Stamping Presses

DDH Series Mechanical Presses

This high-speed metal stamping press adopts a 3 guide post, 8-way roller slide guiding system, ensuring exceptional load capacity and precise alignment. It maintains long-term stability and accuracy even under off-center loading conditions. The extra-wide worktable (3700×1200 mm) supports complex and large-scale stamping applications. With a shut height of 500-560 mm, stroke length of 40 mm, press capacity of 4000 kN, and stroke speeds between 80-200 spm, it is engineered for heavy-duty, high-precision metal forming operations.

- Extra-wide worktable: The 3700 mm-wide table accommodates complex and large components, allowing flexible setup for multi-process operations.

- Stable bottom dead center repeatability: Maintains consistent bottom dead center precision, reducing die wear and product dimensional deviation while extending die service life.

- Minimized thermal displacement: Advanced thermal control technology, derived from small high-speed press applications, minimizes heat-induced deformation and ensures product accuracy.

- High-precision 8-way slide guiding: The 8-way roller slide guiding system delivers superior load-bearing capacity and improved eccentric load tolerance. The extended guiding structure also simplifies long-term maintenance.

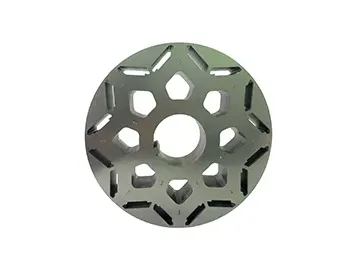

- Rotor and stator lamination stamping and forming

- Rotor and stator lamination stamping and forming

- Metal hardware stamping and forming

- Motor

- Hydraulic lubrication pump

- Oil chiller

- Clutch

- Brake

- Feeding inlet

- Locking pump

- Worktable

- 3 guide posts

- Slide/Die arm bracket

- Die height indicator / hydraulic pressure gauge / air pressure gauge

- Control panel

Outline Dimensions

Technical Specifications

| Press capacity (kN) | 4000 |

| Stroke (mm) | 40 |

| Stroke speed (spm) | 80-200 |

| Shut height (mm) | 500-560 |

| Worktable size (bolster) (mm) | 3700×1200 |

| Slide area (mm) | 3700×1000 |

| Slide adjustment (mm) | 60 |

| Scrap hole size (mm) | 2700×400 |

| Motor (kW) | 90×6P |

Continuously transfers metal coils step by step into the stamping press for uninterrupted production

Used for uncoiling and recoiling rolled metal materials before and after processing

Flattens uneven metal sheets by passing them through upper and lower rollers to achieve uniform surface precision

Collects and cuts waste materials generated during the stamping process to keep the production area clean and efficient

A client from Jiangsu, China, specializes in manufacturing new energy motors. They had previously relied on imported Japanese metal stamping equipment but turned to us after several rounds of discussion and technical evaluation. Currently, three 3700 mm worktable mechanical presses are operating in their facility, contributing efficiently to the growing new energy vehicle industry.