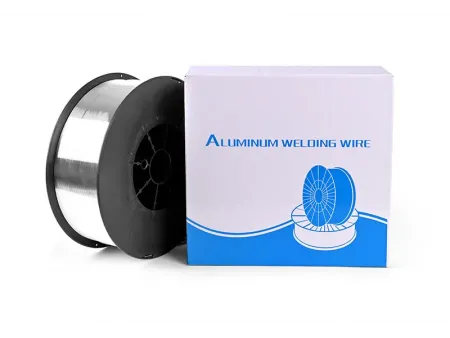

ZL114A (ZAlSi7Mg1A) Aluminium Welding Wire

Request a Quote

Welding Consumables

Aluminium-silicon filler metal for MIG and TIG welding of cast aluminium alloys

- Chemical Designation: ZAlSi7Mg1A

- Standard: GB/T 1173-2013

Chemical Composition (%)

| Si | Mg | Ti | Al | Be |

| 6.5-7.5 | 0.45-0.75 | 0.10-0.20 | Rest | 0-0.07 |

Features

- Developed for welding ZL114A cast aluminium alloys. This type of welding wire offers high strength, excellent flow characteristics, and strong corrosion resistance.

- Commonly used in aerospace, automotive, and military applications where durable and precise joints are required.

- With proper welding parameters and techniques, the welded joints can achieve mechanical performance comparable to the base metal.

- Delivers stable casting behavior with no tendency for hot cracking, minimal linear shrinkage, and high gas-tightness.

- Shows slight susceptibility to porosity and shrinkage cavities, but offers strong corrosion resistance and can be heat-treated for enhanced strength.

- Naturally age-hardenable, offering a good balance of strength, ductility, and weldability, with moderate machinability.

Available Sizes

- Welding wire: 0.8/1.0/1.2/1.6/2.0/2.4/3.0/3.2/4.0/5.0/6.0mm

- Spool: D300 (9kg), D270 (7kg), D200 (2kg), D100 (0.5kg)

Applications

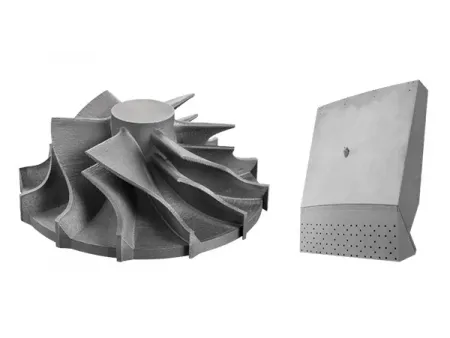

ZL114A aluminium welding wire has strong potential in the 3D printing industry, especially for demanding sectors like aerospace, automotive manufacturing, defense equipment, shipbuilding, and heavy machinery. It works well with technologies such as arc additive manufacturing and laser metal deposition, enabling the production of complex parts that require high strength, corrosion resistance, and reduced weight. Its performance makes it a valuable material in advanced metal fabrication.

Typical applications include:- Aerospace: Used for 3D printing structural parts, engine components, and fuel tanks for aircraft.

- Automotive: Suitable for engine blocks, gearbox housings, chassis structures, and other lightweight parts.

- Defense: Ideal for printing missile casings, rocket engine components, armored vehicle parts, and equipment supports.

- Shipbuilding: Applied in fabricating structural hull elements, marine engine parts, and onboard piping systems.

- Industrial machinery: Used to manufacture durable components such as gearboxes, pumps, valves, and custom mechanical parts.

Packaging

- MIG wire diameter: 0.8mm, 1.0mm, 1.2mm, 1.6mm, 2.0mm

- Package: D300 (9kg/spool), D270 (7kg/spool)

- MIG wire diameter: 1.2mm, 1.6mm

- Package: drum D660 (100kg/drum)

- TIG wire diameter: 2.0mm, 2.4mm, 3.0mm, 3.2mm, 4.0mm, 5.0mm, 6.0mm

- Package: 1000mm length (10kg/box)

- TIG wire diameter: 1.6mm, 2.0mm, 2.4mm, 3.0mm, 3.2mm, 4.0mm, 5.0mm, 6.0mm

- Coil inner diameter: D450mm, D300mm

- Package: 10-17kg/coil

Recommended Welding Method

Use AC current with pure argon shielding gas to ensure optimal results when welding with this aluminium-silicon wire. It supports both MIG and TIG processes, provided the welding area is properly cleaned and kept dry to avoid porosity or surface defects.